Blog

AI-Powered Robots Deliver Reliable Performance During Peak Holiday Shipping Season

AI-Powered Robots Deliver Optimal Performance During Peak Holiday Shipping Season

Historically, rising to the occasion of peak holiday season means hiring armies of temporary workers before Black Friday and hoping that enough stick around to make it through the new year. With the increasing capabilities of AI-powered robots, there is a new alternative: robots can flex to meet demand by increasing utilization and continuously improving year over year.

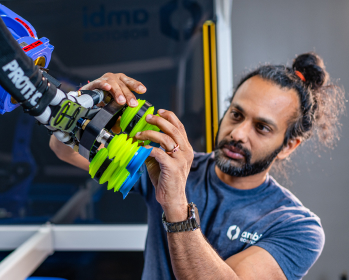

In a recent Forbes Technology Council article, Jeff Mahler, Co-Founder and CTO at Ambi Robotics shares how robots are a fountain of data that enables improvement of your operation. In this article, Jeff reviews a case study of how robots at Ambi Robotics helped meet the demands of peak season in a live commercial operation with improved throughput and accuracy.

Peak Season 2022

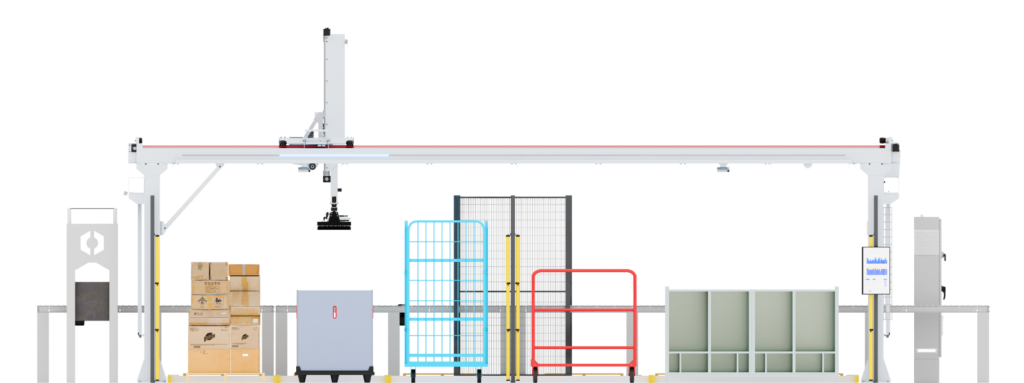

In 2022, Ambi Robotics rolled out dozens of AmbiSort A-Series AI-powered machines for sorting small parcels to sacks with a new customer. Before partnering with Ambi, the customer had a completely manual process in which people sorted by hand at about 180 sorts per hour with significant accuracy issues. In some buildings, as many as 3% of all sorts went to the wrong destination.

The AmbiSort A-Series machines went live in late Q3 and operated through peak season 2022, sorting just over 6 million packages at 355 sorts per hour and 99% sort accuracy. This was a strong start, exceeding the stated performance of 325 sorts per hour and saving over 20% in operating expenses. Nonetheless, there was significant room for improvement.

Improvements Before Peak 2023

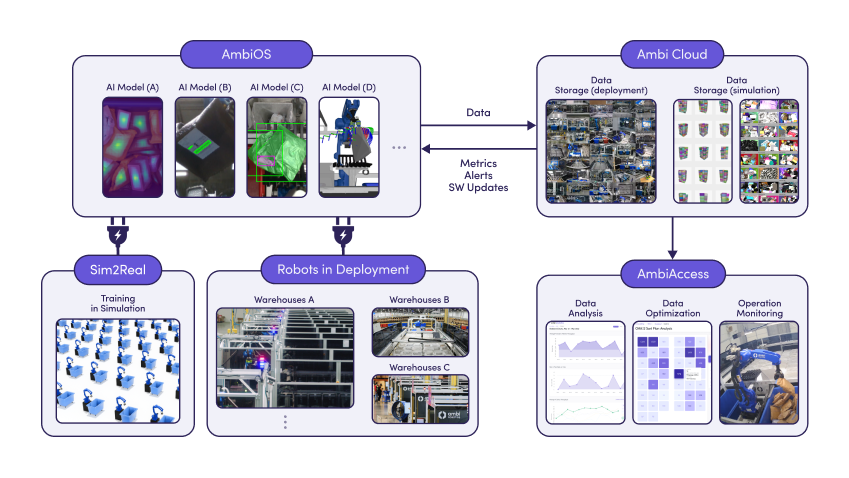

Real-time monitoring systems created the first opportunity. As robots operate, they are tracking every movement, from the position, velocity, and duration to associated images for planning. Manual processes are often standardized off of time studies – in a sense, robots are constantly performing a time study on themselves and we can use the recorded data to improve performance.

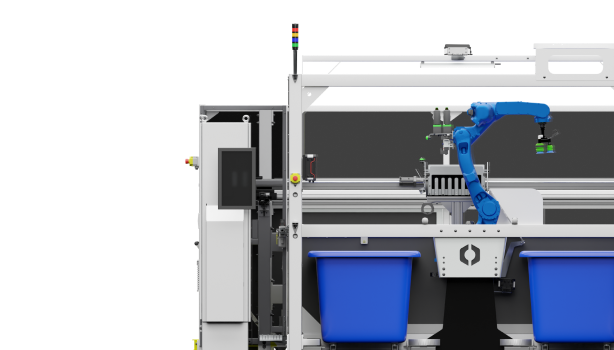

With event replay systems, engineers were able to watch what happened on machine cycles that were longer than average. We found that there was a significant time savings opportunity based on optimizing the robot and gantry motions. The motion planner was switched from a method that used several linear motion segments to one that minimized time all the way through the trajectory, shaving critical milliseconds off of each movement. In addition, we found opportunities to place items on the handoff platform between robot and gantry more reliably, reducing the number of cycles where the robot fails to sort a package. These seemingly minor changes to each cycle led to over a 5% speedup in overall throughput.

Notification systems also led to improvements in operational efficiency by alerting operators and support staff when there was a potential problem leading to reduced performance or downtime. When reviewing robot performance from peak season, the Ambi support team found periods of time where the robot was performing suboptimally. For example, there could be a leak in the vacuum system, leading to failed item picks, or the barcode scanner could get dirty, leading to failed barcode reads. The engineering team used this information to make automated detection and root cause analysis systems for these events with a combination of analytic methods and AI-based classification systems. When an event was detected, both the operator on site as well as the Ambi remote support team would be notified to investigate the root cause and fix it quickly, dramatically reducing the duration of low performance periods.

Continuous learning enabled machine performance to improve further. As the machines collected millions of examples through peak season 2022 and beyond, the training datasets for AI modules like robotic pick planning grew significantly and included a greater diversity of challenging items like polybags. The growing training dataset led to a 7% increase in the pick success rate.

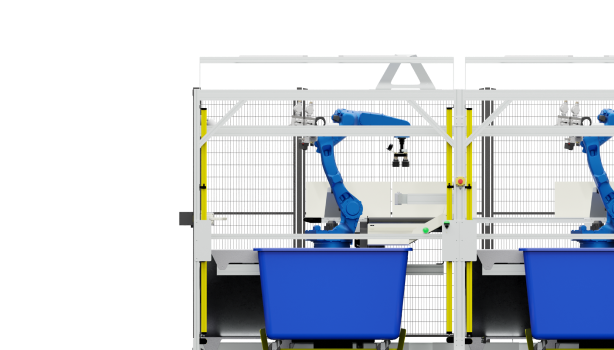

Peak Season 2023

By October of the next year, the same robots were optimized for the customer’s operation, enabling them to handle a significant year over year increase in packages without additional operating hours. Over peak season 2023, the robots sorted 7.4 million packages at 410 sorts per hour. In summary, that translates to:

- 23% increase in the number of packages sorted

- 15% increase in throughput

- Over 35% savings in operating expenses over the previous manual process

Despite the gains, performance is not yet saturated. There is still opportunity to further improve throughput, sort accuracy, and customer savings, all without changing the physical machine.

This story highlights how AI-powered robots are much more than a piece of fixed machinery. They adapt to the unique demands of each holiday season, continuing to improve with more data and freeing operations management to focus on the big decisions.

Peak Holiday Season 2024

For peak season 2024, we’ve made a number of additional updates to improve performance further:

- Added a new AI model architecture for quality control – detecting multiple items on the handoff platform – that increased sort accuracy.

- Improved detection methods for swinging items like large bags to reduce motion speed and avoid missorts, increasing sort accuracy further.

- Implemented new control software for the robot arm and gantry, helping us dramatically increase throughput.

- Refined gantry placement locations to improve the number of items in each sack.

- Added 2D barcode support, reducing the rate of failed scans.

These changes, along with others, increased throughput to 500 sorts per hour and sort accuracy to 99.6%. With these enhancements, we are helping our customers not only manage an unusually intense peak shipping season but also set a new standard for efficiency and reliability, showcasing the transformative potential of robotics in the logistics industry.

Related Articles

-

Blog | 09.09.2025Sandra Kazee Named Winner of 2025 Women in Supply Chain AwardSandra Kazee is recognized for her professional and community achievements for the second consecutive year.

Blog | 09.09.2025Sandra Kazee Named Winner of 2025 Women in Supply Chain AwardSandra Kazee is recognized for her professional and community achievements for the second consecutive year. -

Blog | 07.08.2025Prime Day Is Now a Four-Day Spectacle And One Million Robots Are Running the ShowPrime Day began as a 24-hour sale. Today, it’s a $24 billion, four-day event powered by one million robots and an upskilled workforce built to meet modern customer demand.

Blog | 07.08.2025Prime Day Is Now a Four-Day Spectacle And One Million Robots Are Running the ShowPrime Day began as a 24-hour sale. Today, it’s a $24 billion, four-day event powered by one million robots and an upskilled workforce built to meet modern customer demand. -

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations.

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations.