AI-powered modular parcel induction and sorting solution

A sorting solution built for more

More flexibility

More speed

More uptime

More accuracy

More safety

Parcel induction and beyond

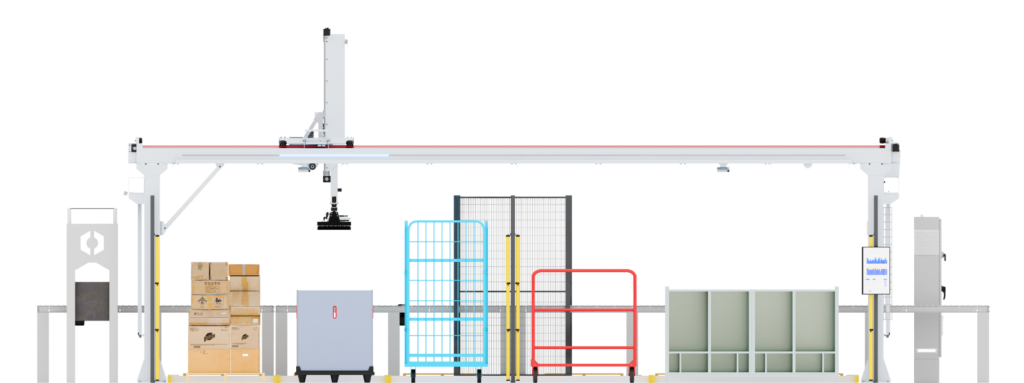

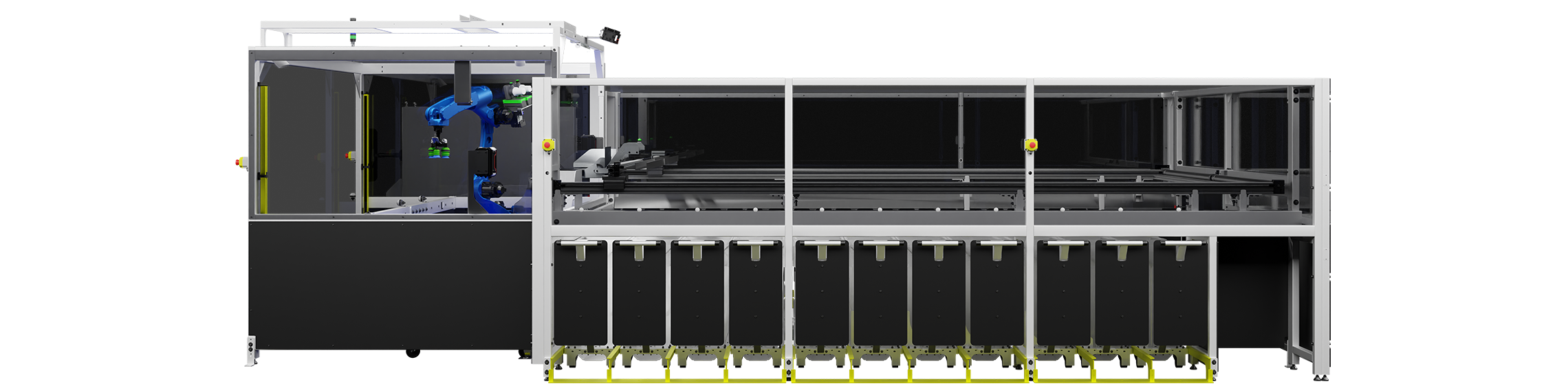

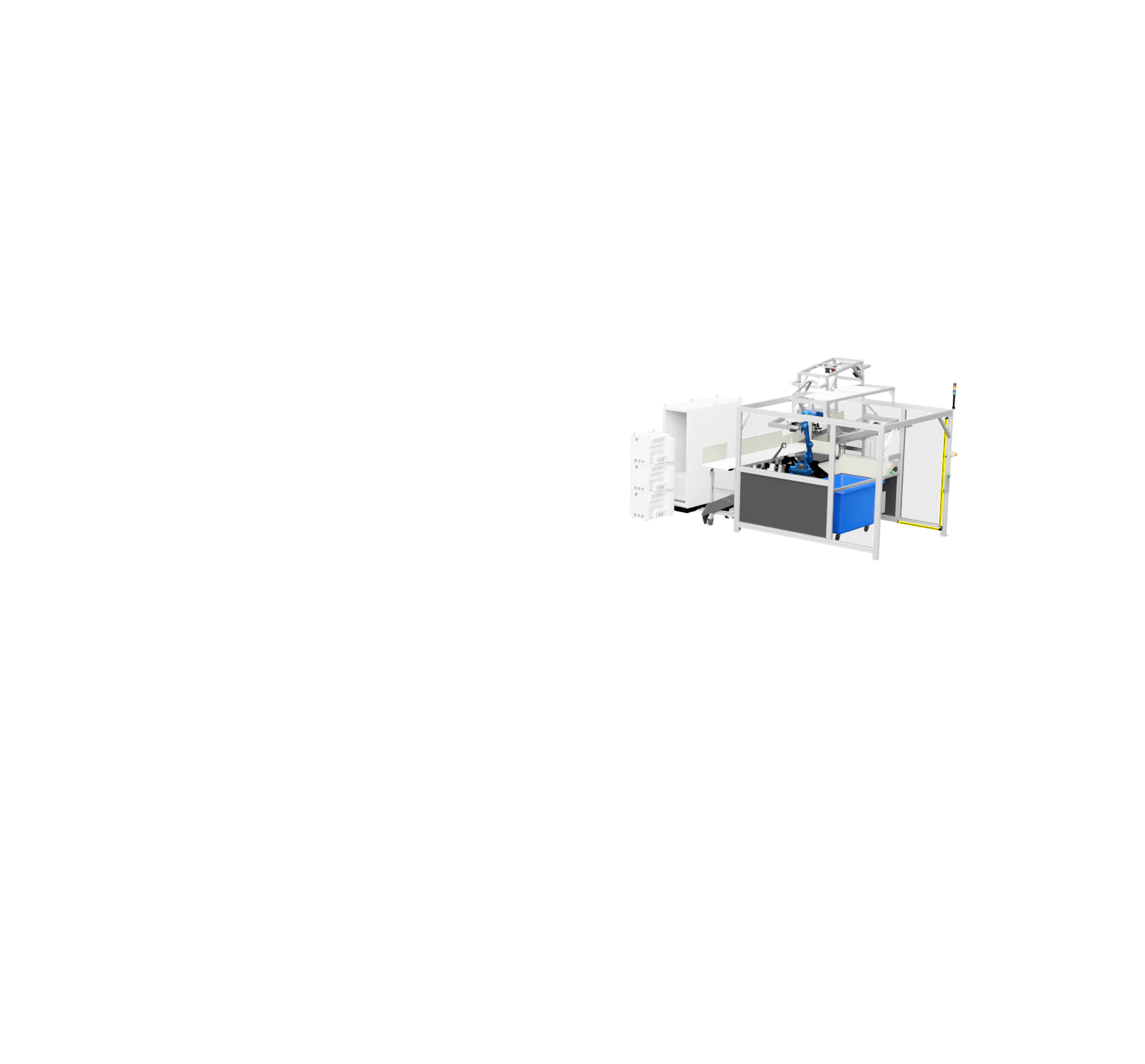

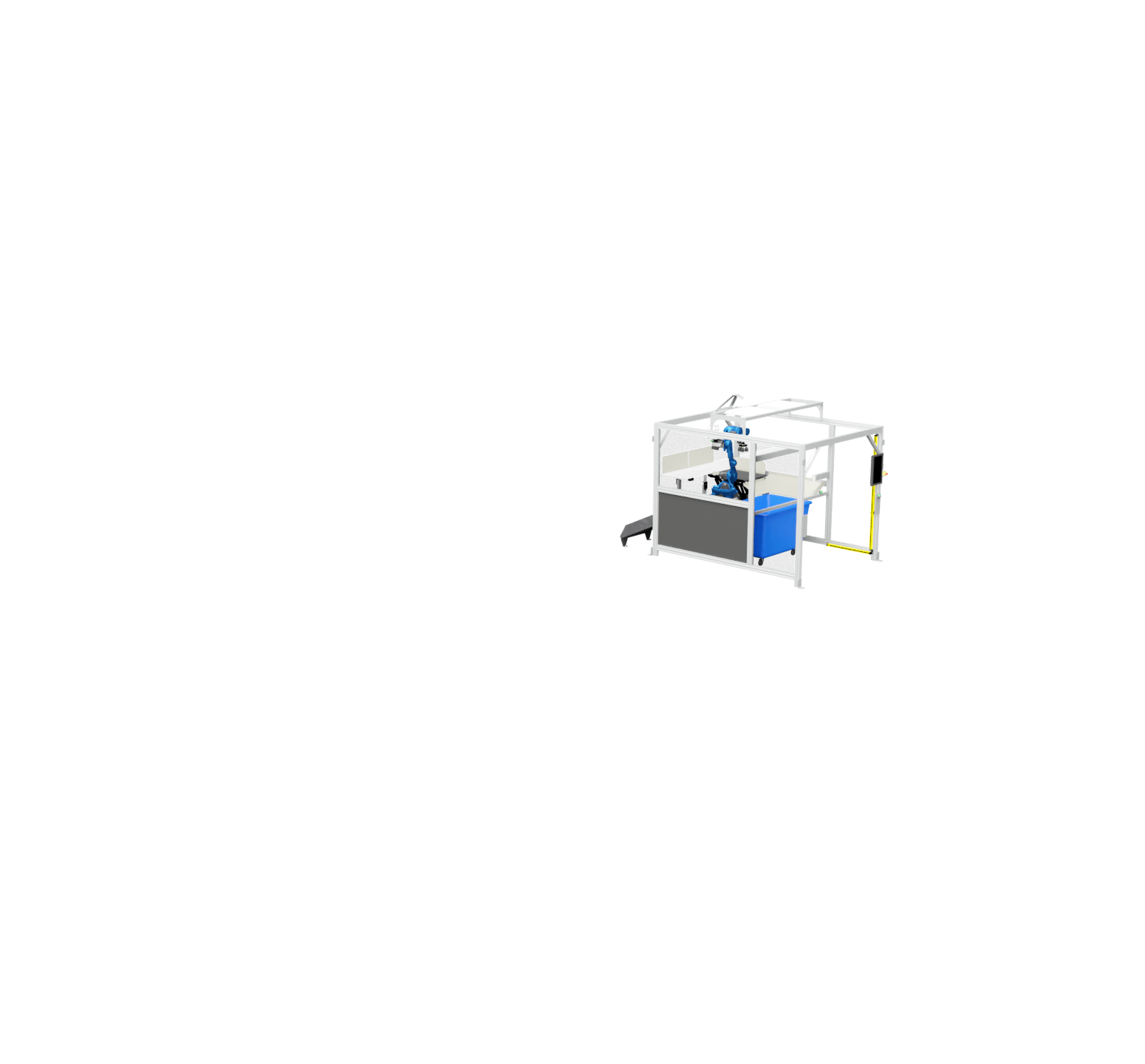

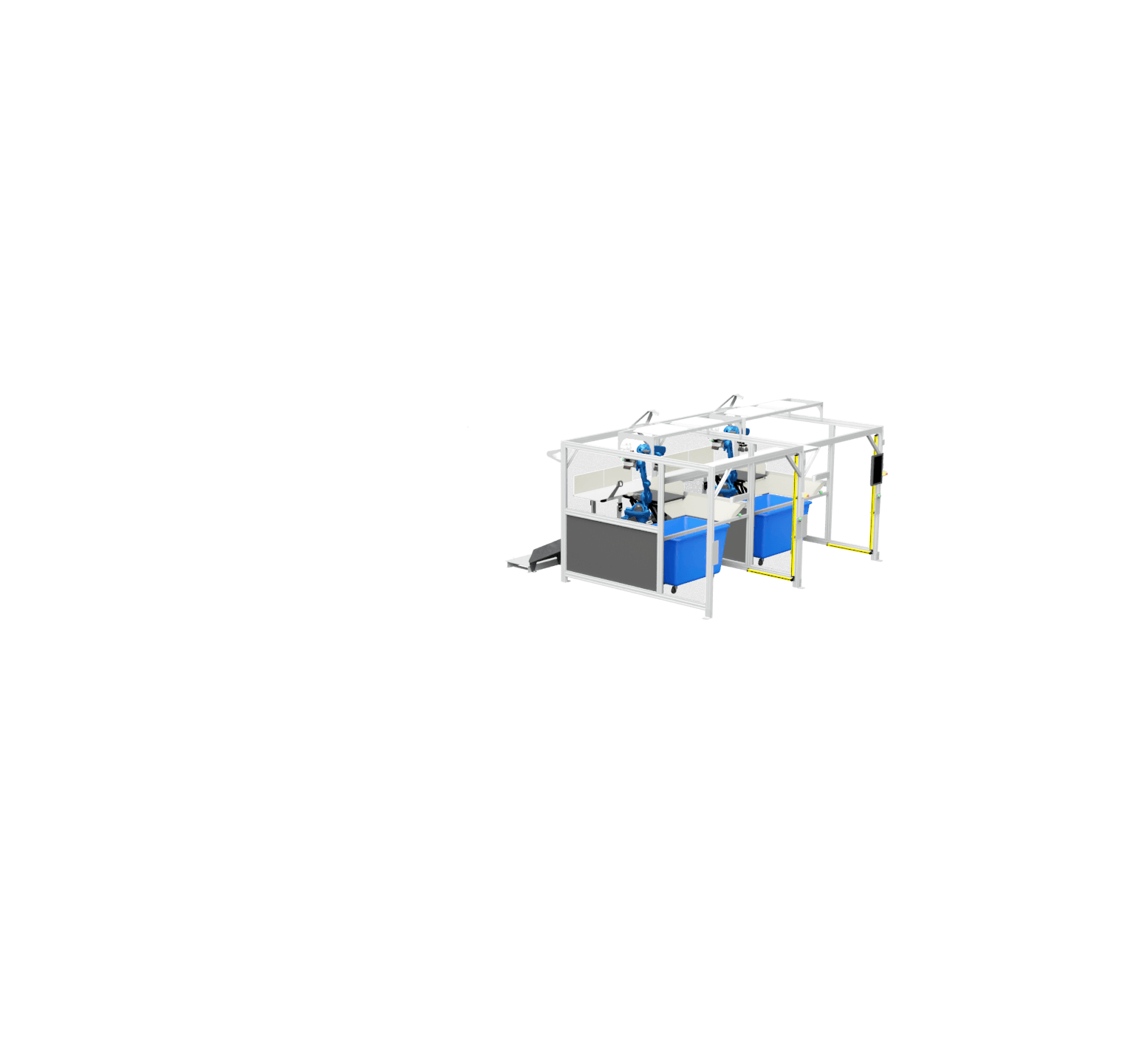

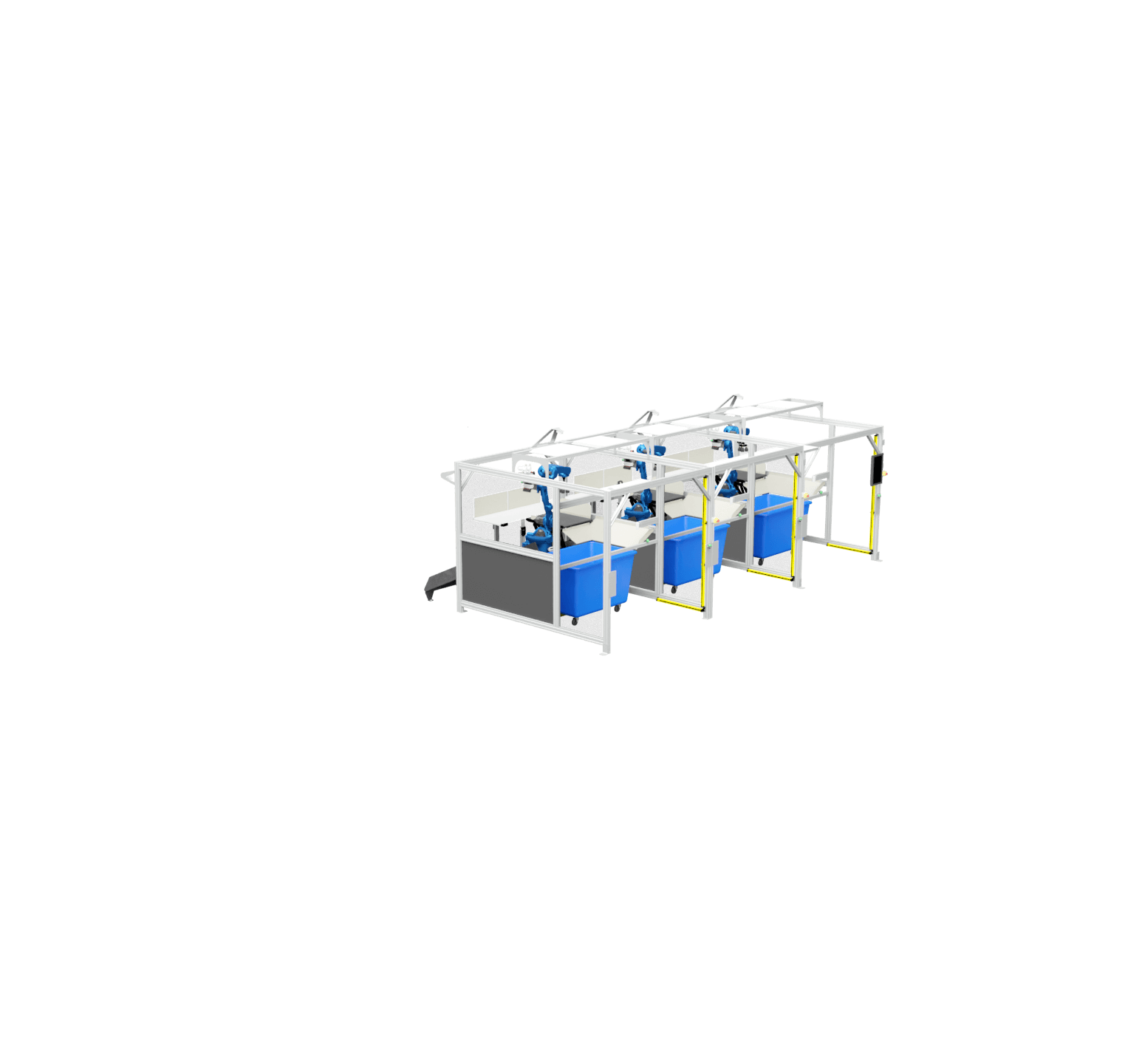

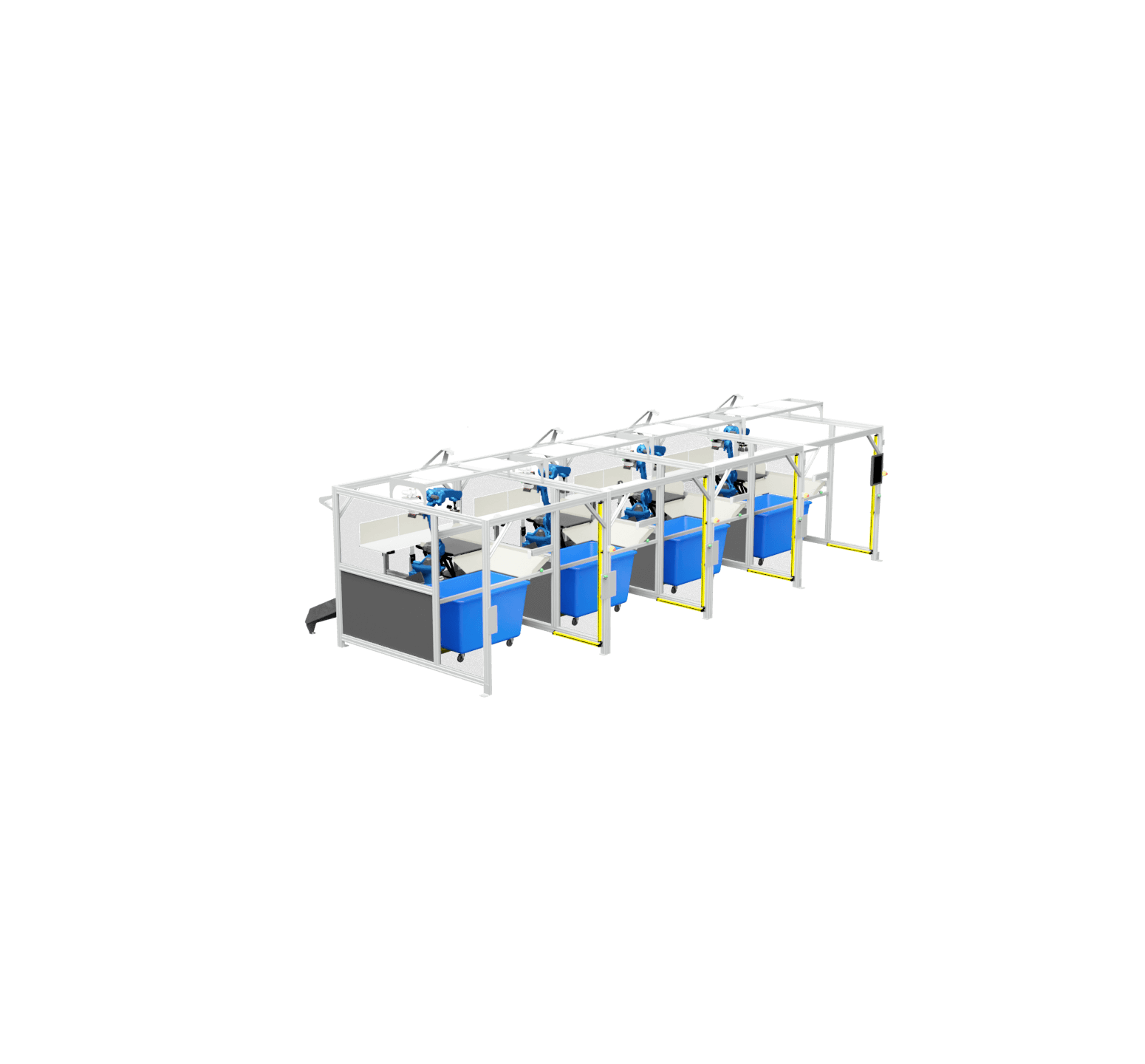

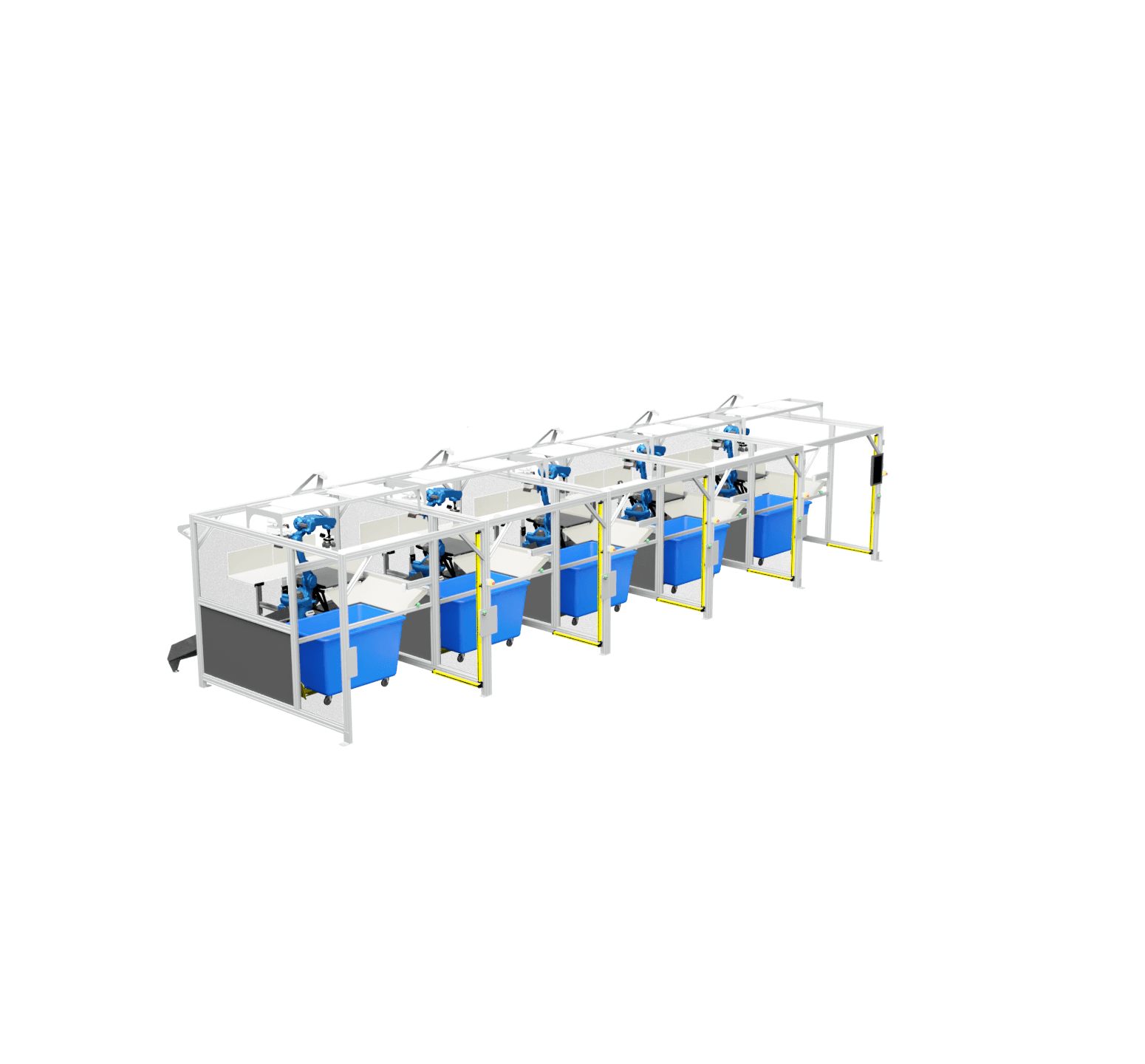

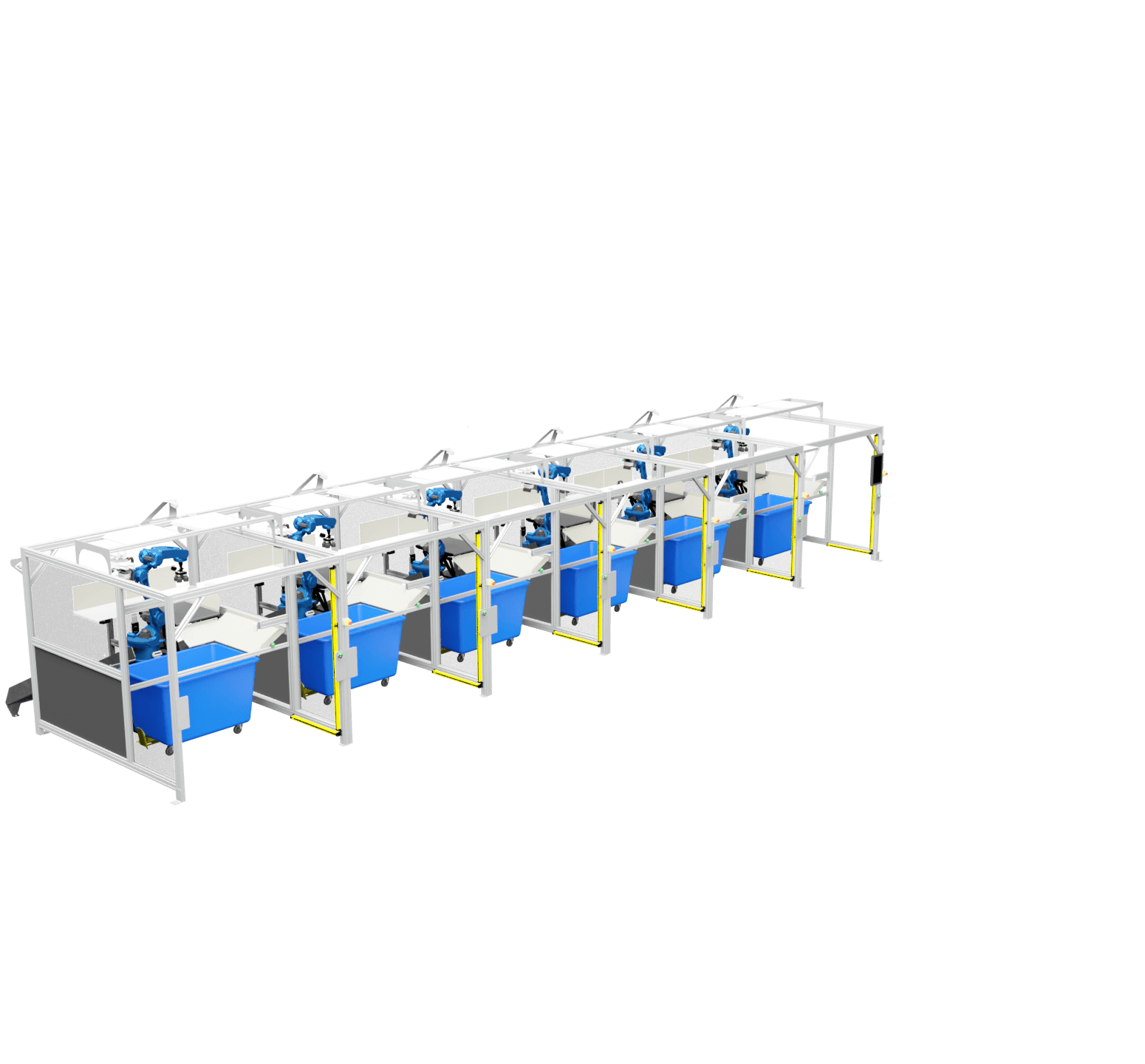

Configurable by design

Build your AmbiSort system today

How it works

-

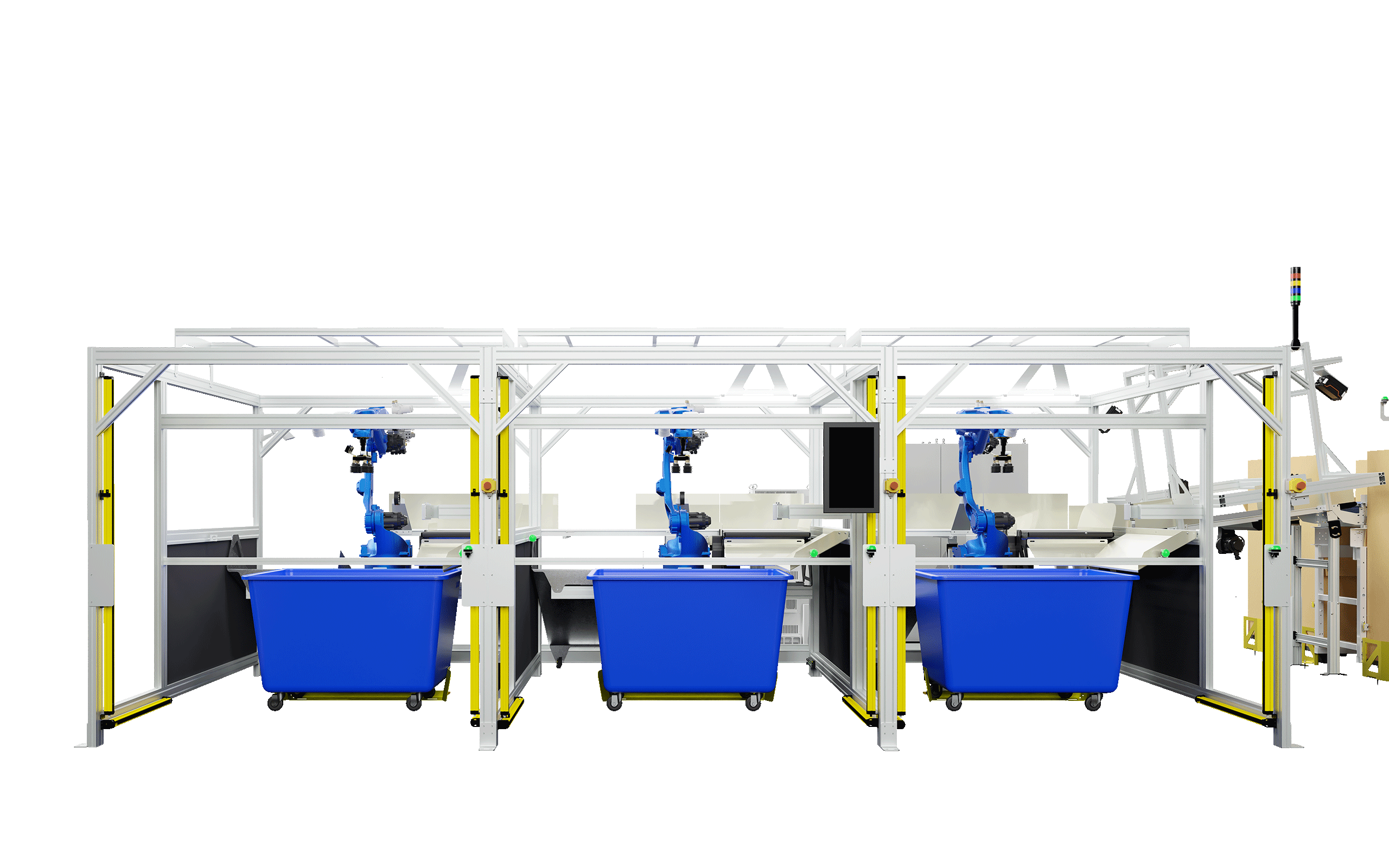

Plan & Identify

- Vision systems capture images of items in unstructured bin.

- AI determines grasp points and motion plans.

-

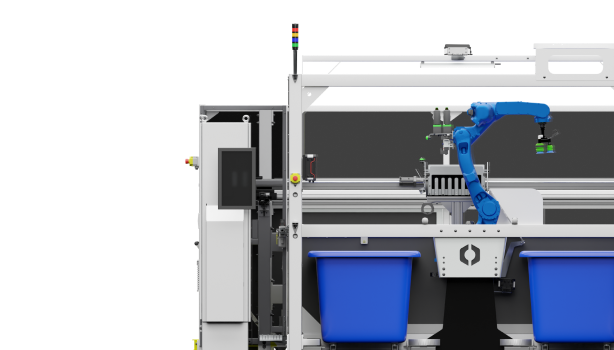

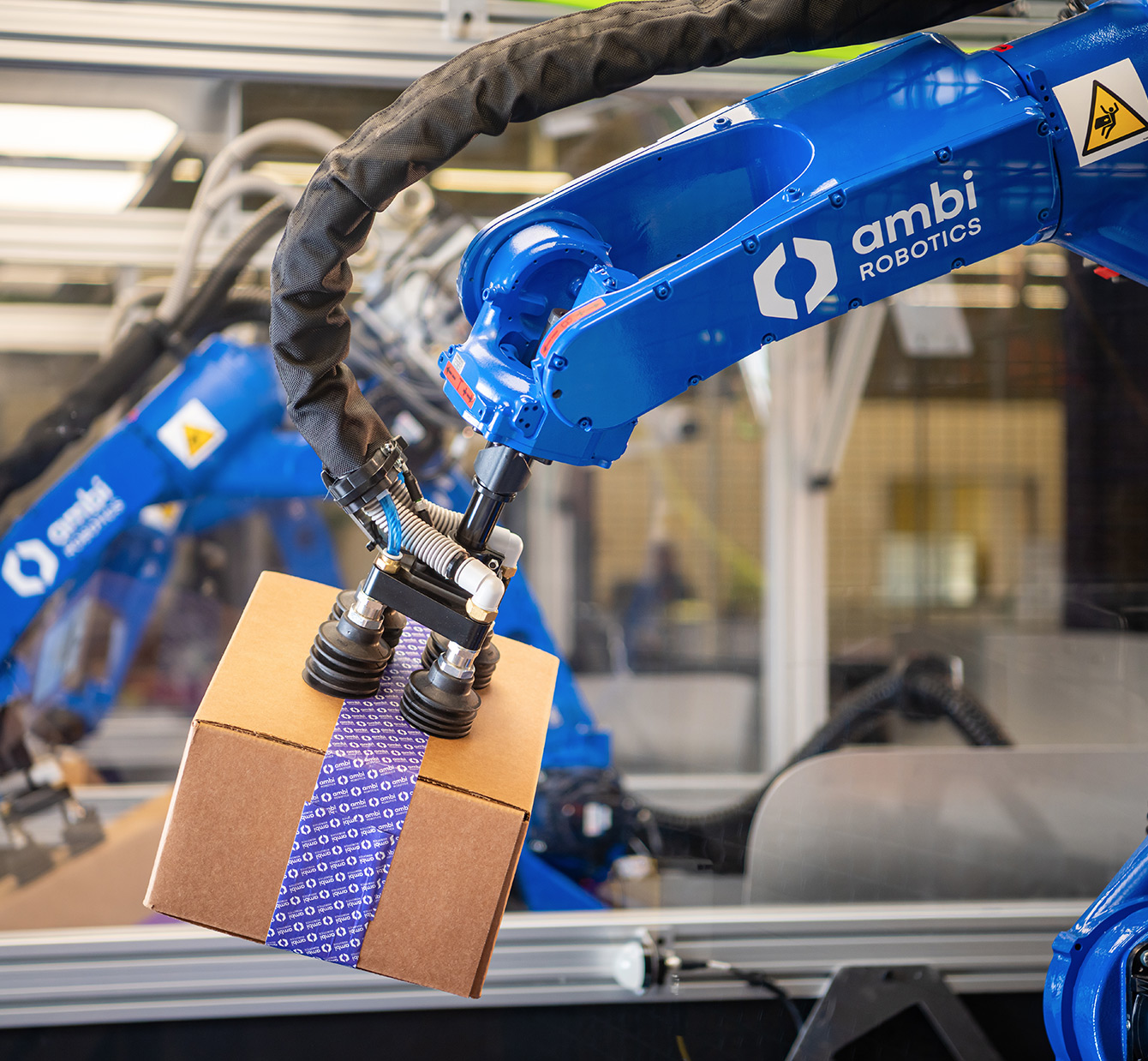

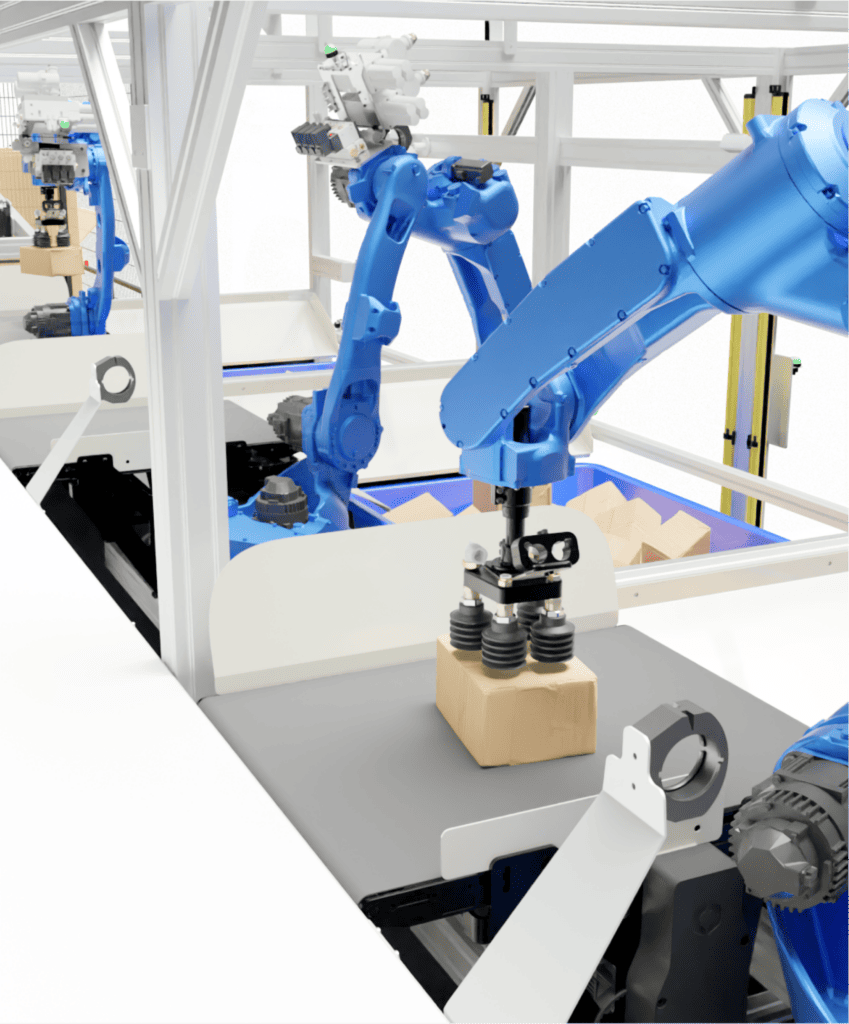

Grasp & Induct

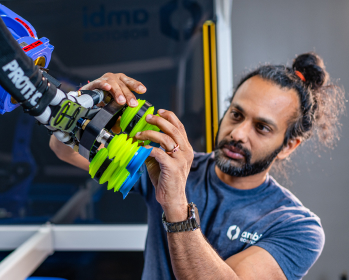

- Intelligent multi-suction gripper singulates and grasps parcels.

- Robotic arm maneuvers and gently places on buffer conveyor.

-

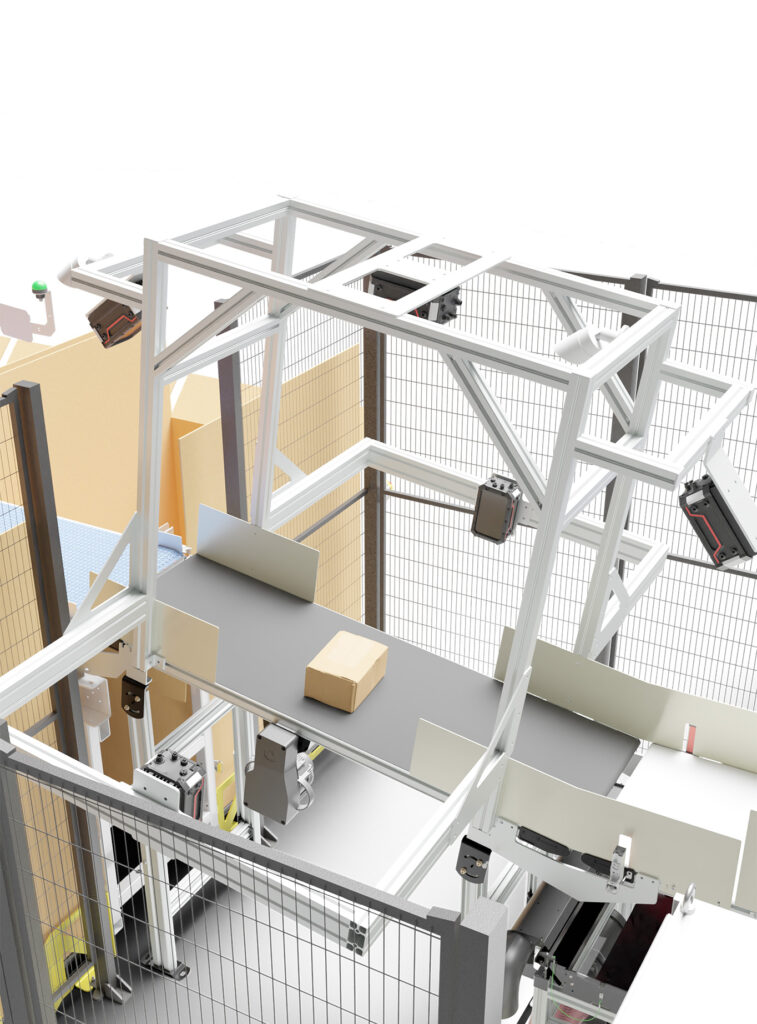

Convey & Scan

- Parcels are transported along a central conveyor to the scan tunnel.

- High-speed six-sided scan tunnel to capture parcel information.

- Decoded barcode data is used to determine the sort location.

- Optional integration with customer WMS system to provide sort locations.

-

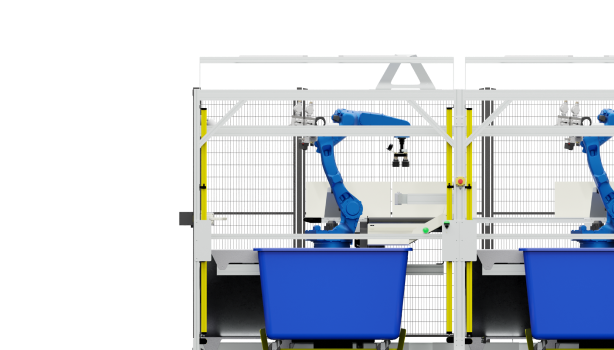

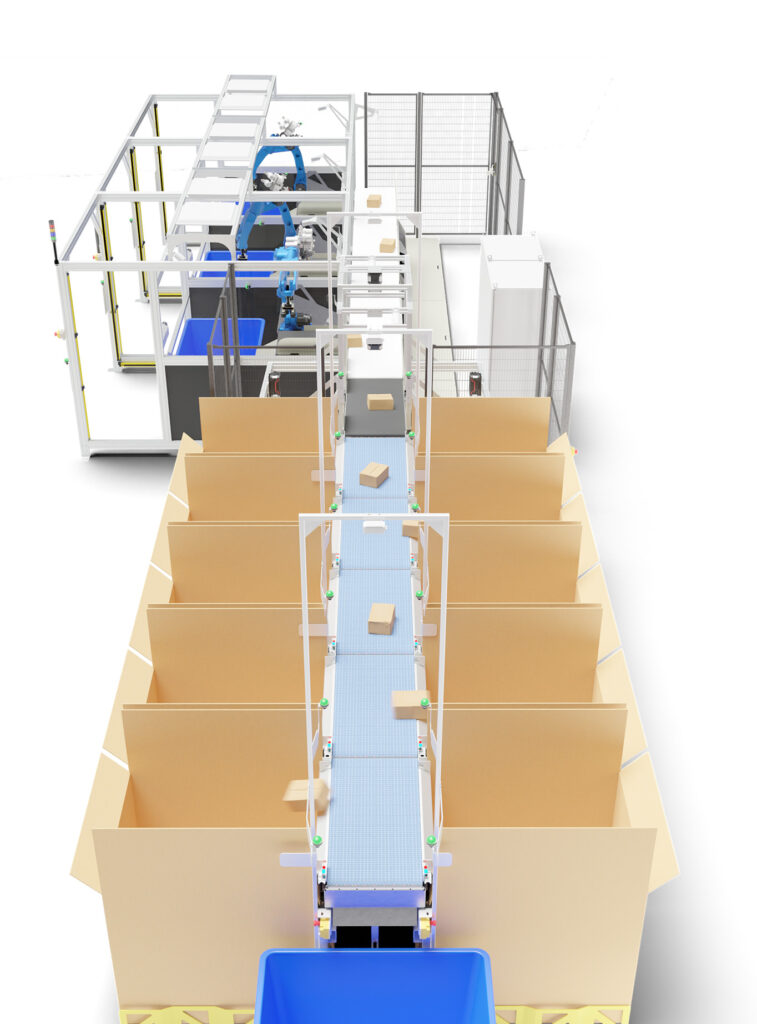

Sort-to-Gaylord

- Parcels are sorted to designated gaylords or autonomously rerouted to reject bin

- Gaylord fill levels are continuously monitored by overhead vision systems.

- Light indicators notify operators when gaylords are full

Are you ready to handle more?

Technology that delivers

-

Ready on day one

10,000 times faster training means our robots are ready to go — right from day one.

-

Adaptable AI

Modular hardware allows for flexible configurations for various package material flows.

-

Continuous learning

Over time, processes are analyzed and optimized using image, video, timing, and performance data.

-

Item analysis

Collect data on parcel dimensioning and material identification

-

Quality control

Prevent double picks with vision-based analysis

-

Smart notifications

Stay ahead of potential issues with real-time notifications for proactive problem-solving

Built to commercialize at scale

We provide AI-powered robotic solutions for sorting challenges that help you optimize your warehouse operations for maximum efficiency.

B-Series: Built for More.

In the news

-

Newsroom | 05.30.2023Ambi Robotics Optimizes Sorting Operations with AmbiAccessAmbiAccess, a cloud-based business intelligence tool from Ambi Robotics, helps customers maximize their Robots-as-a-Service (RaaS) investment.

Newsroom | 05.30.2023Ambi Robotics Optimizes Sorting Operations with AmbiAccessAmbiAccess, a cloud-based business intelligence tool from Ambi Robotics, helps customers maximize their Robots-as-a-Service (RaaS) investment. -

Newsroom | 10.17.2022Ambi Robotics Raises Funding for New Kind of Warehouse RobotA startup called Ambi Robotics has raised $32 million to put a new kind of robot into ecommerce warehouses.

Newsroom | 10.17.2022Ambi Robotics Raises Funding for New Kind of Warehouse RobotA startup called Ambi Robotics has raised $32 million to put a new kind of robot into ecommerce warehouses. -

Newsroom | 01.04.2022The 2022 Supply Chain: Prioritizing People, Customers, TechnologyExecutives from the largest logistics companies and global retailers are turning to AI and robotics to solve some of their most challenging tasks throughout the supply chain

Newsroom | 01.04.2022The 2022 Supply Chain: Prioritizing People, Customers, TechnologyExecutives from the largest logistics companies and global retailers are turning to AI and robotics to solve some of their most challenging tasks throughout the supply chain