AI-powered robotic small parcel sorting to the last-mile

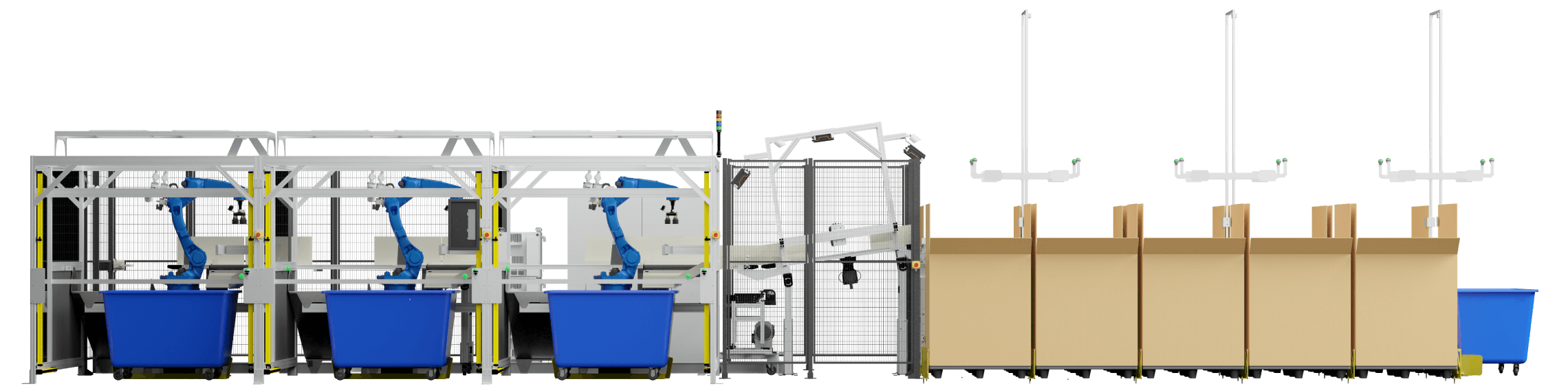

Effortless to integrate.

Easy to scale.

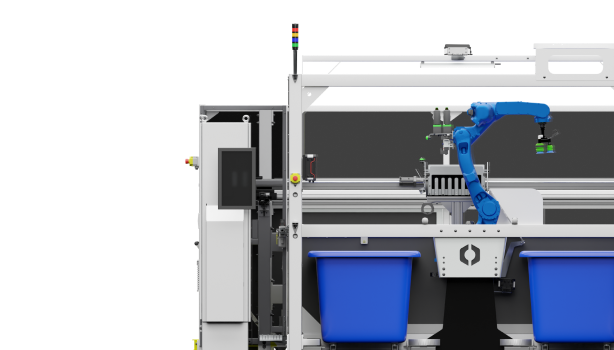

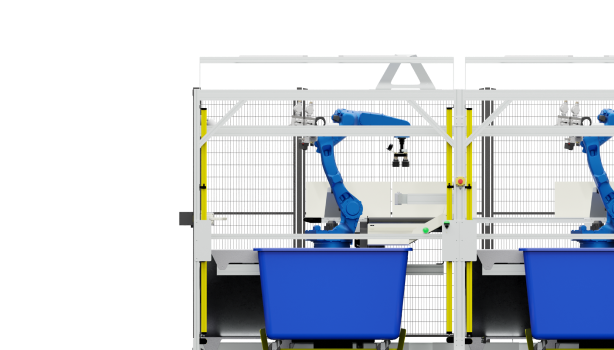

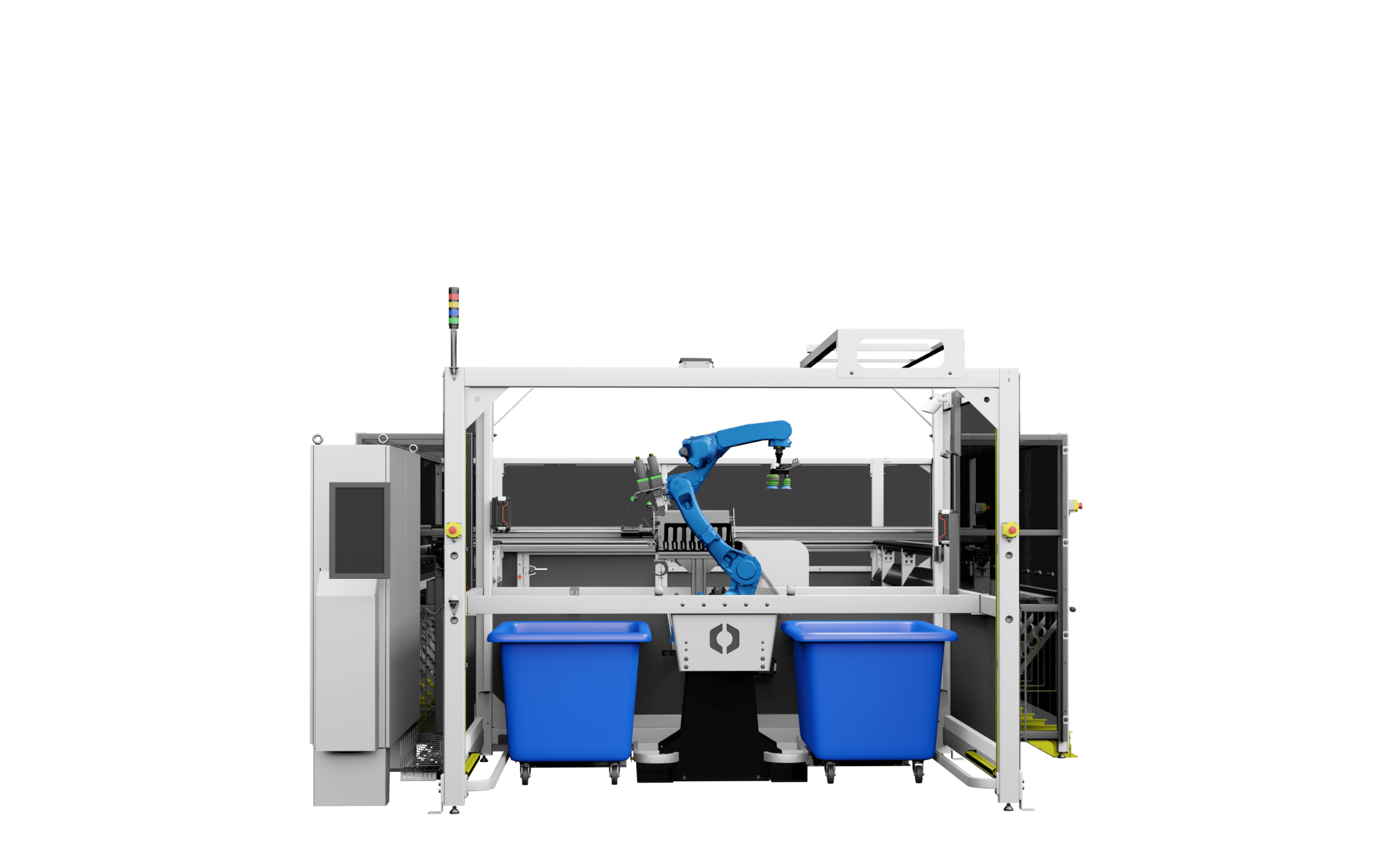

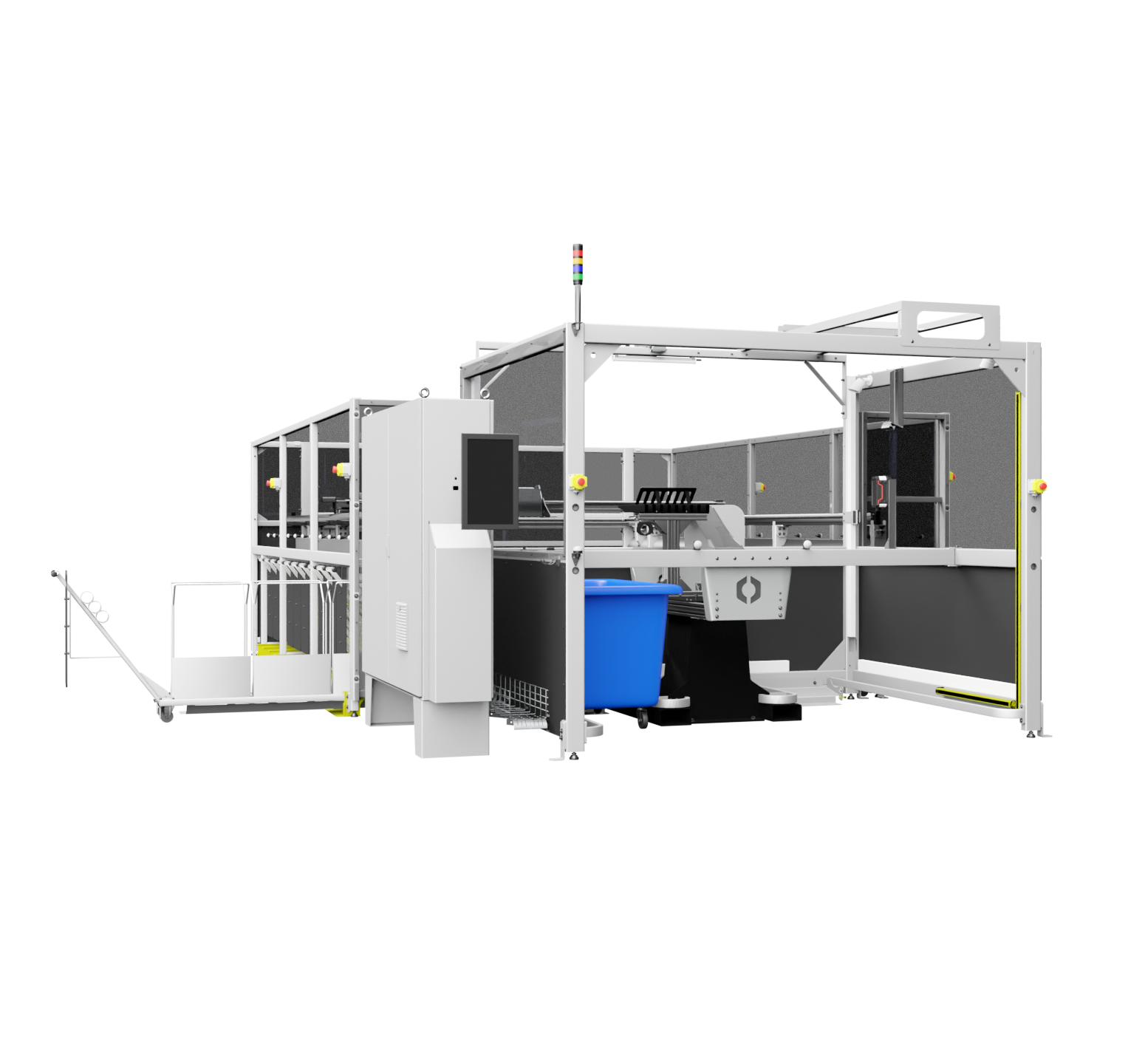

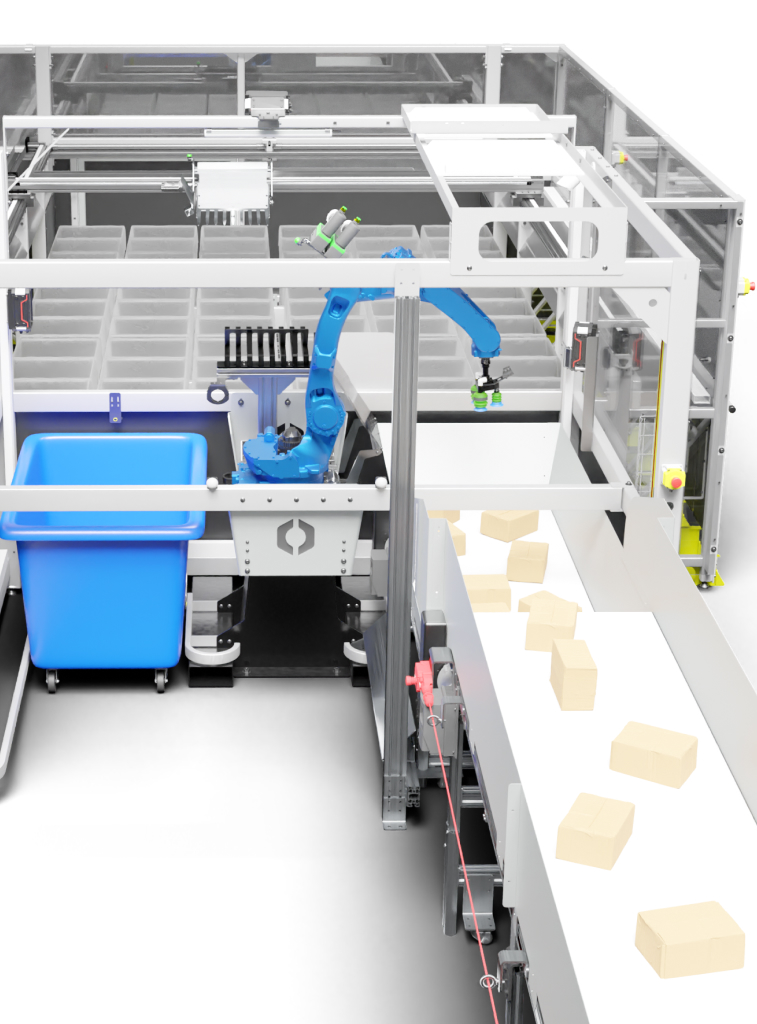

Select your input

- Bin-fed

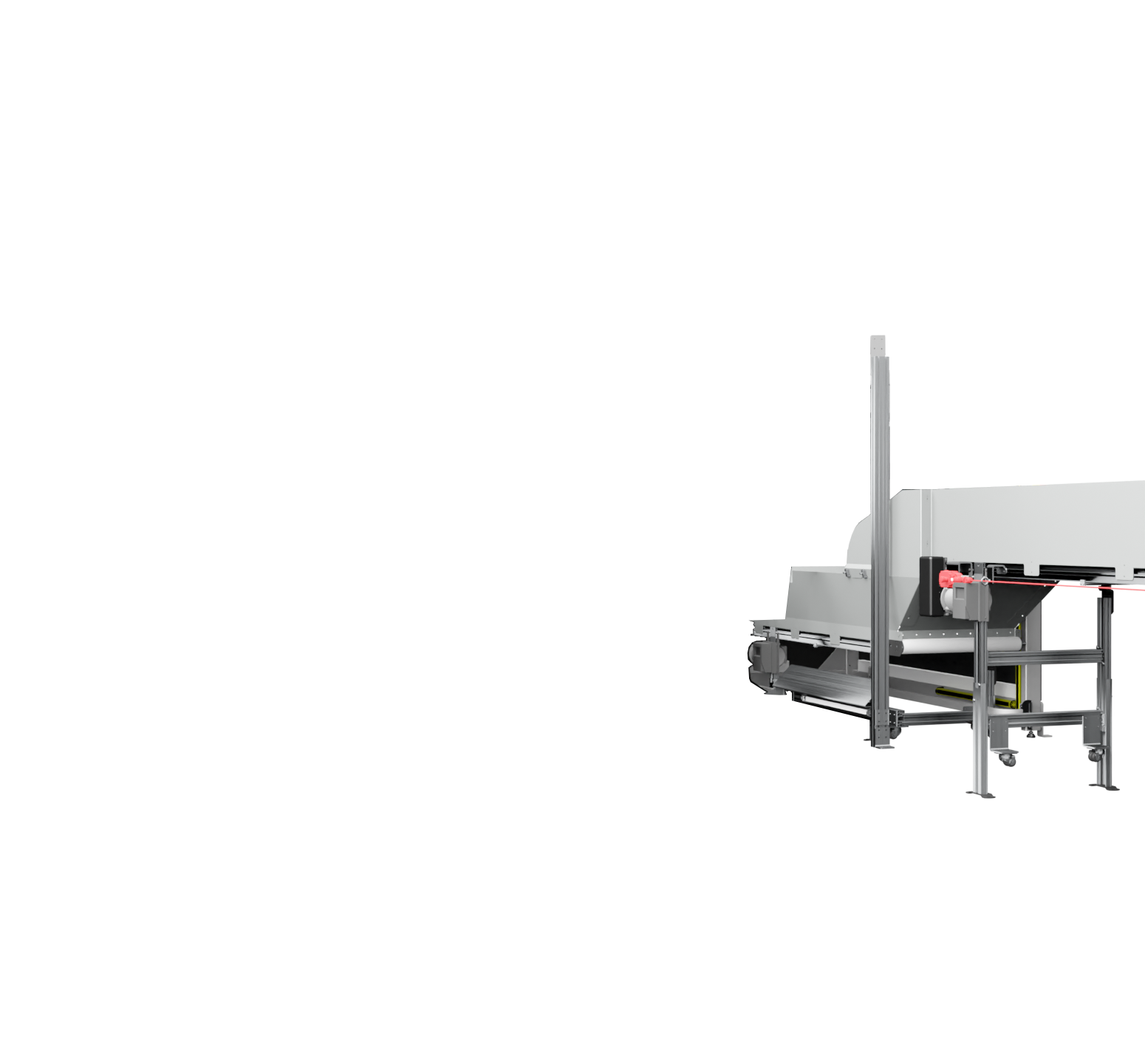

- Conveyor-fed

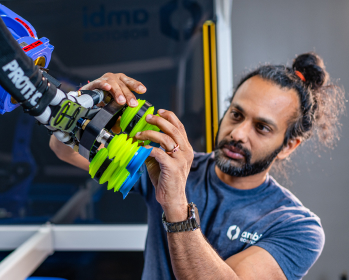

AI-powered. Human operated.

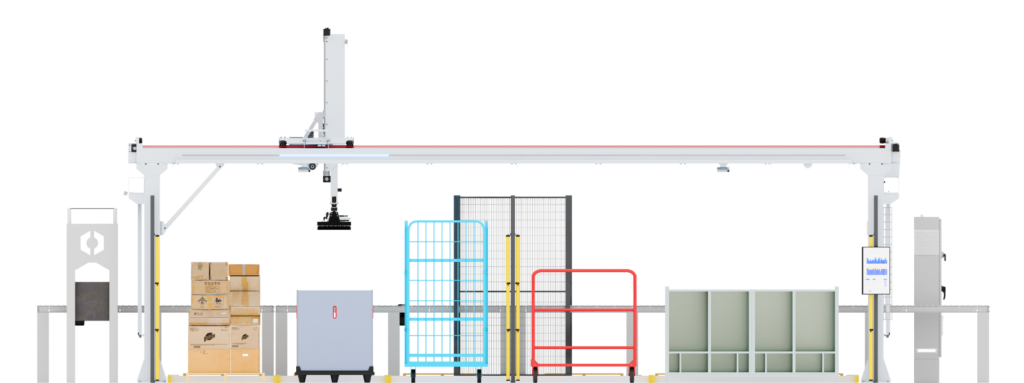

Configurable by design

Build your AmbiSort system today

How it works

-

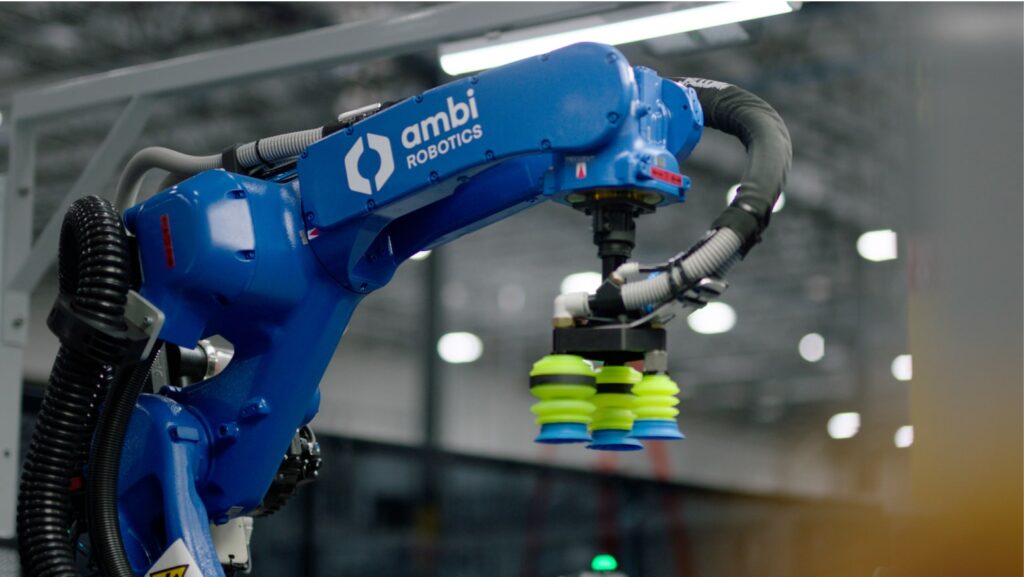

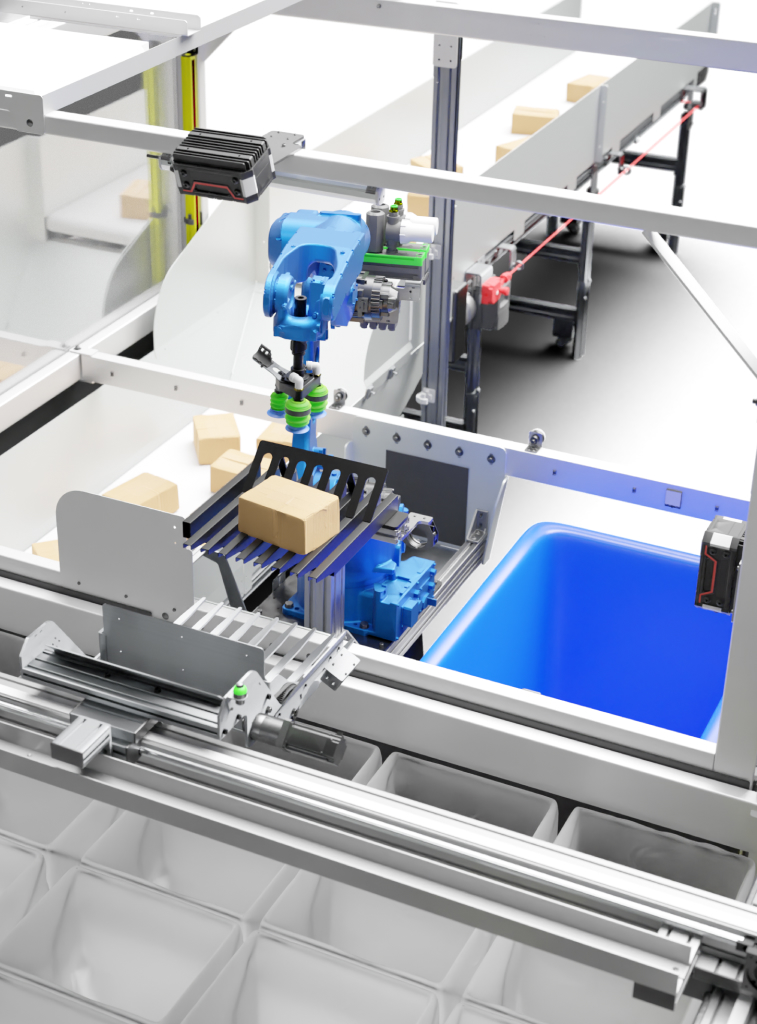

Identity & Grasp

- Vision systems capture images of items.

- AI determines grasp points and motion plans.

- Soft-touch gripper picks up the item.

-

Scan & Quality Control

Each parcel passes across four barcode scanners and through two quality control zones. This determines where to drop-off the item.

-

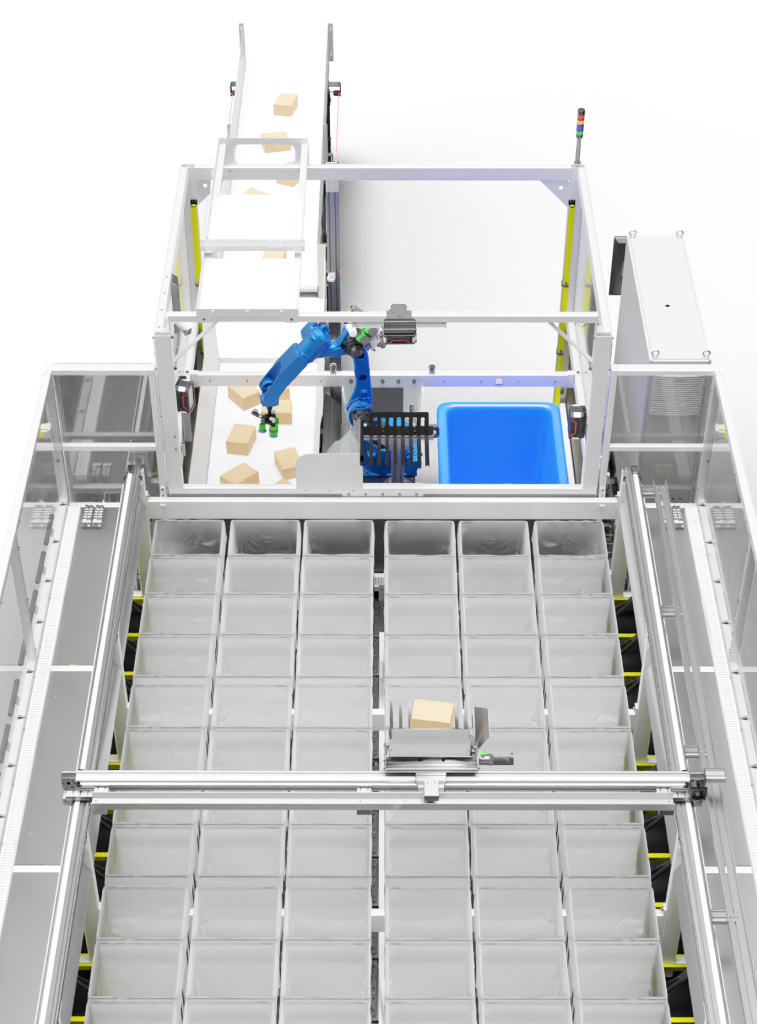

Transfer to gantry & Drop into sack

- Gantry picks up item from the buffer and drops it into the sack.

- Vision systems monitor the fill height of the sack.

-

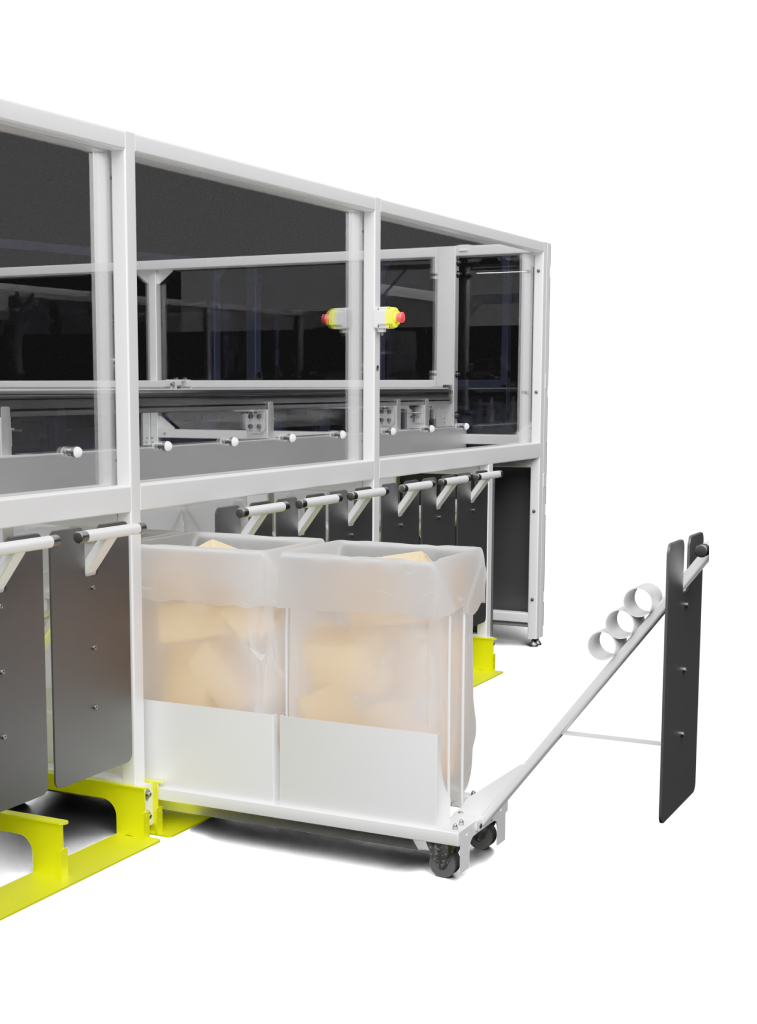

Mailsack replacement

Operator removes and seals full sack using attached strap, then restocks cart with an empty sack.

Ready to handle more?

Technology that delivers

-

Ready to start sorting

10,000 times faster training means our robots are ready to go — right from day one.

-

Adaptable AI

Modular hardware allows for flexible configurations for various package material flows.

-

Continuous learning

Over time processes are analyzed and optimized using image, video, timing, and performance data.

-

Item analysis

Collect data on parcel dimensioning and material identification.

-

Quality control

Prevent double picks with vision-based analysis.

-

Smart notifications

Stay ahead of potential issues with real-time notifications for proactive problem-solving.

Built to commercialize at scale

We provide AI-powered robotic solutions for sorting challenges that help you optimize your warehouse operations for maximum efficiency.

Success stories

In the news

-

Newsroom | 03.17.2022Ambi Robotics and Pitney Bowes sign $23 million expansionPitney Bowes opted for the expansion after using Ambi’s robots in its Stockton, California ecommerce hub.

Newsroom | 03.17.2022Ambi Robotics and Pitney Bowes sign $23 million expansionPitney Bowes opted for the expansion after using Ambi’s robots in its Stockton, California ecommerce hub. -

Newsroom | 03.14.2023Ambi Robotics Deploying Parcel Sorting Robots at OSM Worldwide WarehousesAmbi Robotics is deploying its parcel sorting robots at OSM Worldwide’s warehouses in the U.S. Based on the minimum four-year robots-as-a-service (RaaS) deal.

Newsroom | 03.14.2023Ambi Robotics Deploying Parcel Sorting Robots at OSM Worldwide WarehousesAmbi Robotics is deploying its parcel sorting robots at OSM Worldwide’s warehouses in the U.S. Based on the minimum four-year robots-as-a-service (RaaS) deal. -

Newsroom | 10.17.2022Ambi Robotics Raises Funding for New Kind of Warehouse RobotA startup called Ambi Robotics has raised $32 million to put a new kind of robot into ecommerce warehouses.

Newsroom | 10.17.2022Ambi Robotics Raises Funding for New Kind of Warehouse RobotA startup called Ambi Robotics has raised $32 million to put a new kind of robot into ecommerce warehouses.