Blog

The Power of Hardware-Software Codesign

Synergy from the start matters. Just look at the simple act of drinking a glass of water.

When it involves just yourself, taking a sip of water can be the definition of routine. Your hand, eye, and mouth work in sync to see the glass, pick it up, and drink from it without spilling. That’s the way your body as a whole is designed; to work as a single, coordinated tool.

However, It can be a bit more challenging when you’re helping someone else drink from that glass of water. Your hand and eyes are working in tandem to move the glass, but the drink recipient is an unfamiliar target with a mind of its own that lacks the instant synergy when you bring the glass to your own mouth. It takes more work, creating a greater margin of error and perhaps less efficiency and effectiveness because you’re retroactively combining two tools that didn’t pre-sync.

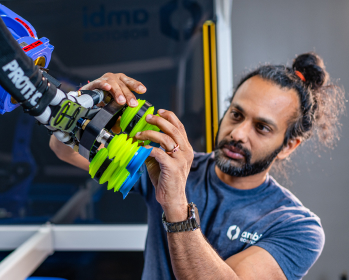

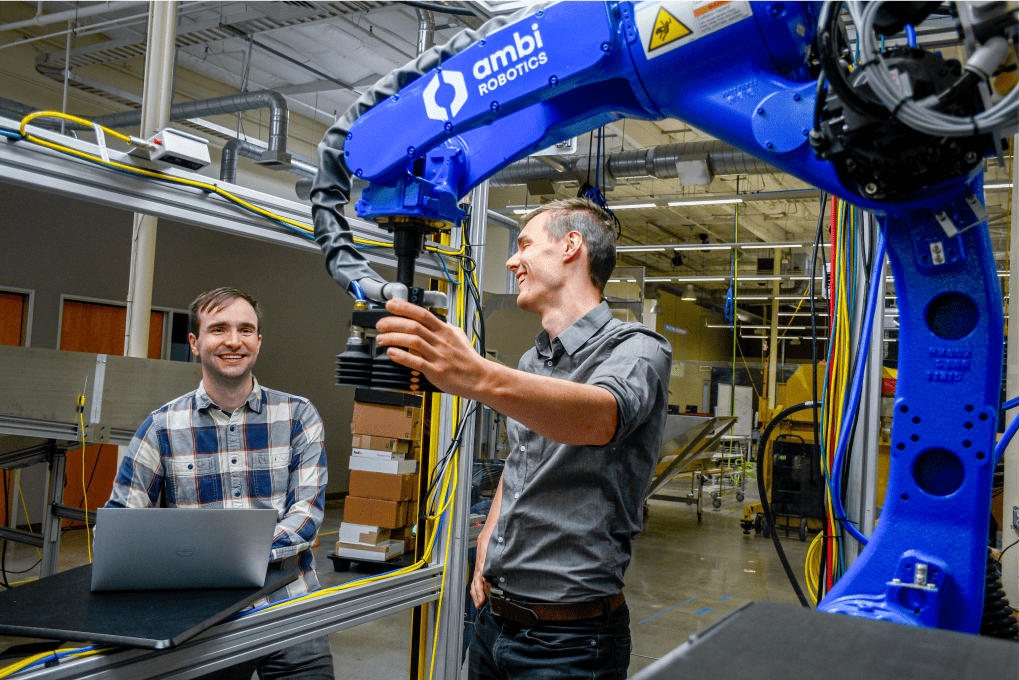

In the world of warehouse robotics, synchronization is what makes hardware-software codesign a critical advantage. In traditional robotics development, hardware and software are designed and built separately, often by different companies. “If you’re a robotics company, a lot of people focus very much on the software, and then try to entirely purchase off-the-shelf components. They’re not very interested in thinking hard about the hardware designs or hiring proper mechanical engineering teams,” says Matt Matl, Vice President of Software and Co-Founder of Ambi Robotics.

“The design process often includes a market survey for available technology, an attempt to try to put the pieces together in the simplest way possible with a limited hardware knowledge base, and then layering software on top of it,” Matl says. “Engineers have to patch a lot more holes and try to solve a lot of software problems that don’t belong. Maybe I’m trying to solve a difficult picking problem, but it would be a lot easier if my gripper were optimized for the things I’m picking.”

Codesign’s ‘continual back-and-forth’ optimizes products

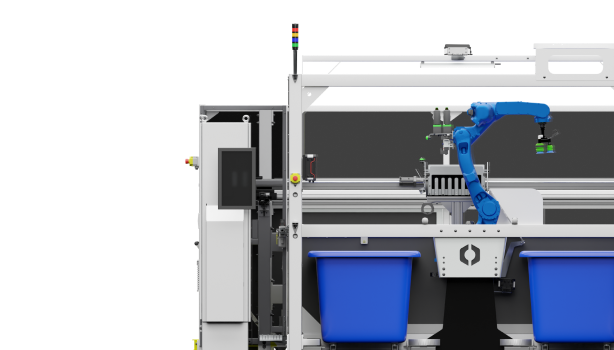

In hardware-software codesign, the brains and the brawn of the robotic system evolve as one, with the goal of empowering people and robots to work well together from the start. And that’s how Ambi Robotics goes about its work.

“Hardware forms the basis of our layouts or designs. It’s what’s going to physically interact with the world. And then software comes in and fills the gaps, or works together with hardware to iterate,” Matl says. “You can have an initial mechanical prototype, add software on it, see where the software fails, and then revise the hardware again to improve where the software doesn’t work.”

“It’s a continual back-and-forth where you try to build in and fill in each others’ capabilities gaps. It’s not just a one-time handoff, but an iterative process,” Matl adds. Over time, “the back-and-forth decreases and you winnow down to your final design, which gets shipped” as a finished – and optimized – product.

Through codesign, Ambi Robotics is “breaking down the traditional barriers of the notion ‘I’m either a software company or I’m a hardware company,’ and it allows you to iterate much quicker,” says Matl.

After all, the goal isn’t to simply design hardware or software; rather, it’s about “meeting the problem with a holistic, balanced solution,” says David Gealy, Vice President of Hardware and Co-Founder of Ambi Robotics. “You’re trying to take into account the strengths and weaknesses of each technology and bring them to the table where they shine strongest.”

Matl framed the benefit in a sports analogy: “Let’s say you’re playing tennis doubles, and you have each person with blinders on, not looking at what the other is doing or not being able to communicate, or you’re only allowed to talk to your partner every three weeks,” he says. “You’re not going to reach the same level of coordination or teamwork, and you won’t put together your full game.”

“If you‘re sitting next to each other working in harmony trying to solve problems – and you determine whose strengths or weaknesses can fill in and complement each other, you’re going to have a very solid tennis doubles team,” Matl adds.

Boundaries become benefits, not blockers

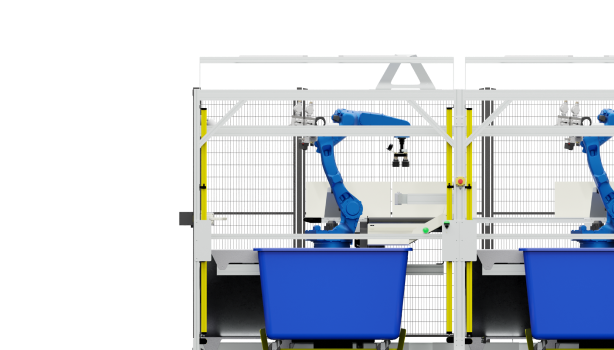

The codesign method and mindset help optimize tangible connections across team boundaries where inefficiency, inconsistencies, and other issues often fester.

“When looking at an organization’s boundaries within itself, you first determine the location of the problem. Where are the problems going to come up? It’s going to be at the boundaries between those products or the services in between those organizations,” Gealy says. “Because within each organization, people generally have solid alignment and are solving the right problems, but it’s always within the boundary.”

“So if you have one organization responsible for the software and the intelligence but another organization responsible for the gripper and the integration, you’ll inevitably have mismatches between the two companies,” Gealy adds.

Beyond Hardware, Beyond Software

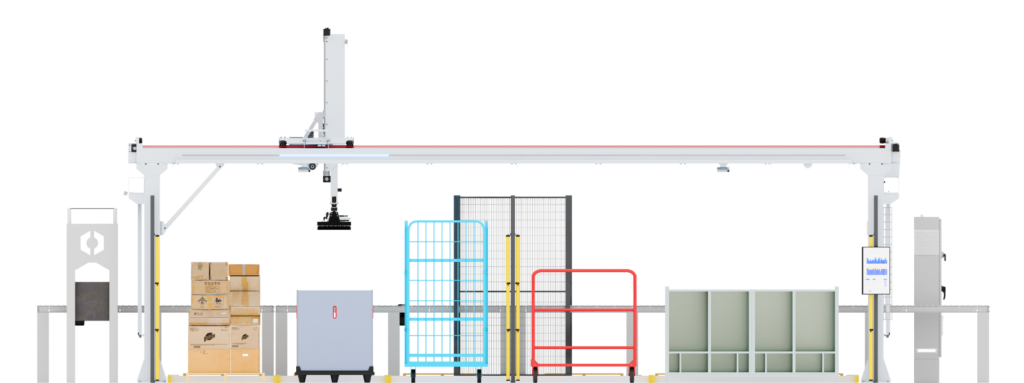

In the end, breaking the boundaries through codesign unlocks tremendous capabilities for Ambi Robotics systems that surpass the limitations of legacy systems. For example, our AmbiOS operating system forms a single unit with our AmbiSort robot arm to enable:

- 10,000 times faster training, meaning robots are ready to pick up parcels immediately

- Out-of-bin accuracy and uptime of more than 99% while sorting more than 325 parcels per hour

- As much as an 80% improvement in throughput

So, how does Ambi Robotics primarily see itself? Are we a hardware or software vendor? The answer is neither – because our philosophy of hardware-software codesign enables us to be so much more. We don’t just sell off-the-shelf robots, we design human-centric solutions that empower our customers to handle more.

“It seems so simple: get the right people together, talk it out, and then keep talking and keep communicating. And keep that spark of curiosity alive,” Gealy says. “Curiosity is the thing that drives it from all sides.”

Related Articles

-

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations.

Blog | 01.30.2025PRIME-1: Scaling Large Robot Data for Industrial ReliabilityWe've achieved critical mass of high-quality data and launched PRIME-1, an AI foundation model for warehouse operations. -

Blog | 11.22.2024AI-Powered Robots Deliver Reliable Performance During Peak Holiday Shipping SeasonDiscover how AI-powered robots revolutionize peak holiday season with enhanced speed, accuracy, and cost savings year over year.

Blog | 11.22.2024AI-Powered Robots Deliver Reliable Performance During Peak Holiday Shipping SeasonDiscover how AI-powered robots revolutionize peak holiday season with enhanced speed, accuracy, and cost savings year over year. -

Blog | 07.17.2024Interns of Ambi Robotics, Summer 2024 EditionMeet Ambi Robotics' Summer 2024 interns! Discover how these curious minds are innovating in AI-powered robotics and supply chain solutions.

Blog | 07.17.2024Interns of Ambi Robotics, Summer 2024 EditionMeet Ambi Robotics' Summer 2024 interns! Discover how these curious minds are innovating in AI-powered robotics and supply chain solutions.