Press releases

Ambi Robotics Transforms Ecommerce with New AI-Powered Multi-Robot Kitting System

New AmbiKit system drives supply chain resilience for next-generation ecommerce

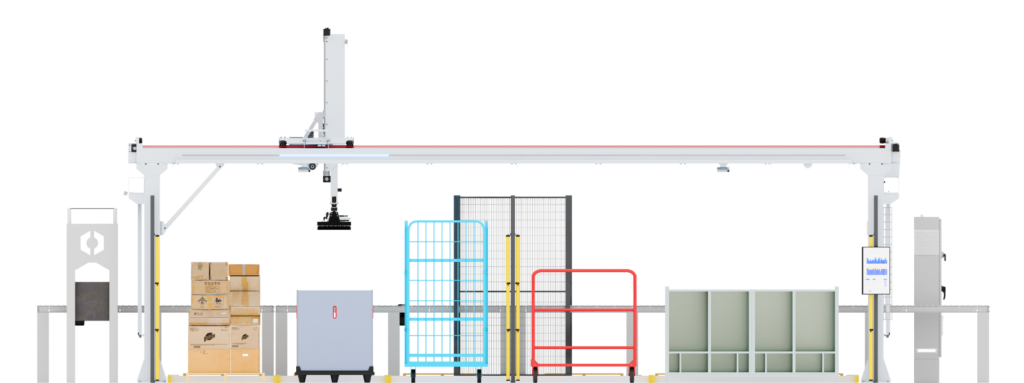

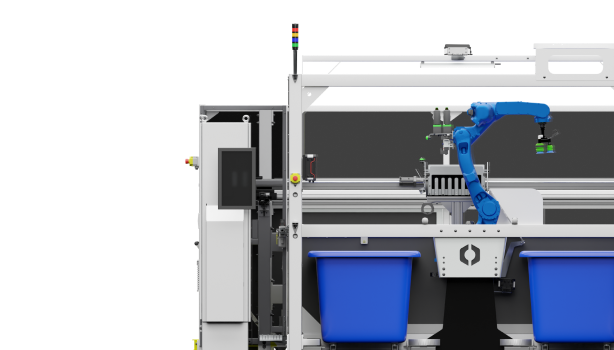

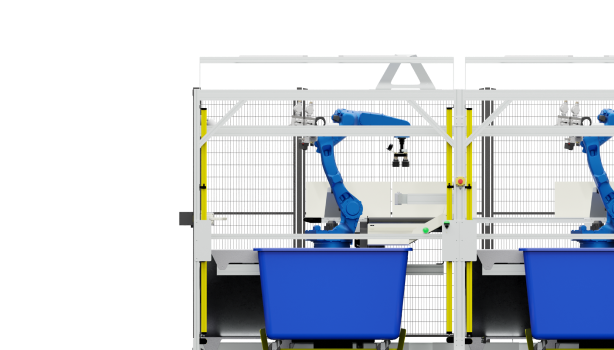

EMERYVILLE, Calif. – July 27, 2021 – Ambi Robotics, the pioneer in simulation-to-reality AI for highly-dexterous robots, today introduces AmbiKit, the industry’s first multi-robot kitting system that leverages AI data collection to expedite ecommerce kitting operations. AmbiKit automates product bundling for faster delivery, increasing order accuracy and reducing operating costs. The new kitting system includes a five-robot picking line, currently deployed to augment the pick and place tasks associated with one of today’s fastest growing ecommerce opportunities: online subscription boxes.

“Retailers and global ecommerce brands are operating in a year-round ‘peak’ season,” says Jim Liefer, CEO of Ambi Robotics. “In order for high-growth brands to fulfill online orders, companies are deploying AI-powered robotic systems to increase resilience in the supply chain. AmbiKit can immediately improve efficiency by deploying into existing workflows and successfully pick and place millions of unique items from day one.”

AmbiKit picks and packs millions of unique products into specific bags or boxes for shipping to online customers. Leveraging state-of-the-art AI with highly-dexterous robotics, AmbiKit ensures more than 99% order accuracy and can operate around the clock with zero downtime for product changeover. While legacy systems take hours, or days, to adapt to new products introduced into a subscription box, AmbiKit quickly personalizes customer orders at scale to increase throughput.

AmbiKit is successfully sorting up to 60 items per minute in a commercial production environment. The kitting system alleviates existing manual warehouse processes for kitting operations that can cost retailers millions of dollars annually due to human error, high employee turnover and employee injury.

The subscription ecommerce kitting market is expected to exceed $478 billion by 2025 and consumers are demanding more product choices than ever before, shaping new trends like personalization and select-item bundling from individual SKU’s. AmbiKit empowers brands to offer on-time deliveries, order customization, and maintain competitive pricing with reduced operating costs.

According to the Federal Reserve District, employment opportunities are on the rise but post-COVID hiring is a widespread challenge. As ecommerce volume continues to surge, companies seek automated solutions to tackle the mundane, repetitive sorting tasks to fulfill online orders and are hiring full-time talent to work alongside advanced technologies.

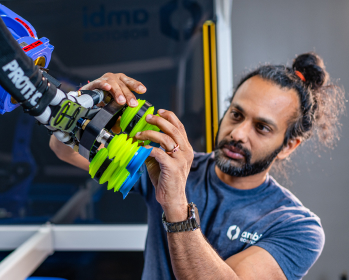

“Ambi Robotics has developed state-of-the-art simulation-to-reality AI that can adapt to perform in any hardware configuration,” says Jeff Mahler, Chief Technology Officer at Ambi Robotics. “Our advanced AI operating system powers a wide range of robotic solutions. When we launched Ambi Robotics, we made the decision to tackle the complex problems in the supply chain first, during a time when the U.S. relied on global ecommerce and logistics more than ever before.”

Onfloor associates work alongside the AmbiKit system to induct totes with product and pack complete kits to be shipped to the end-customer. The AI-powered robotic system guides associates while sorting products to complete external actions through intuitive interfaces and dashboards.

About Ambi Robotics

Ambi Robotics is an artificial intelligence (AI) and robotics company developing advanced solutions that scale e-commerce operations to meet demand while empowering humans to work smarter. The company’s industry-leading AI operating system, AmbiOS, leverages Dex-Net simulation-to-reality technology to operate highly dexterous robotic systems. Founded in 2018, the world’s top roboticists, AI researchers, and leading business professionals work together to build the supply chain’s most valued systems. The company is located in Emeryville, Calif. For more information, please visit www.ambirobotics.com.