Blog

How Robots are Bringing Big Data to the Warehouse

With the explosion of ecommerce during the COVID-19 pandemic, the magic of filling a virtual shopping cart and receiving goods 24 hours later has become commonplace. However, it’s far less common to understand the true scale of processes that move packages from a storage facility to your front door. Behind the scenes, each package is sorted numerous times as it travels from source to centralized hubs to localized shipping routes. Over 23 billion parcels were estimated to have shipped in 2021 in the US alone, resulting in approximately 100 billion individual packages sorted manually.

From Parcel Handler to Robot Operator

Convincing people to sort packages by hand is harder than ever. Not only is the work tedious, but it’s highly injury-prone and carries a high risk of exposure to COVID-19. Unsurprisingly, people quit these jobs in droves. Some companies report turnover rates as high as 90%. That is almost all of their full-time employees leaving each year. Shipping companies can no longer sustain themselves purely by hiring more people. They need modern solutions.

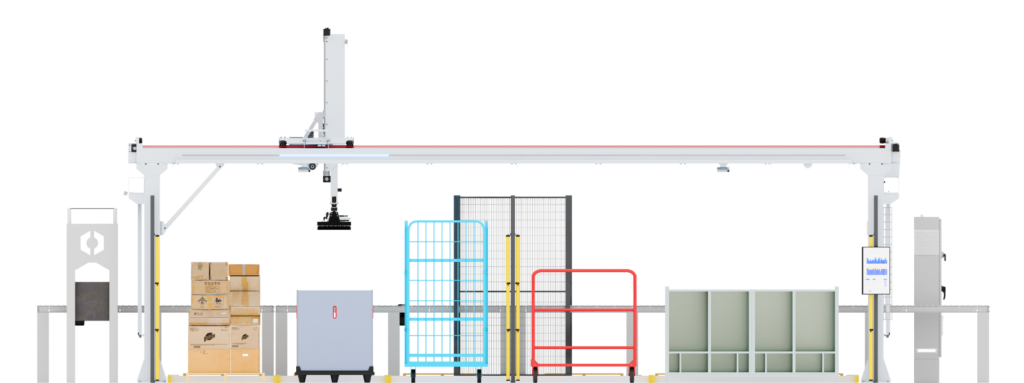

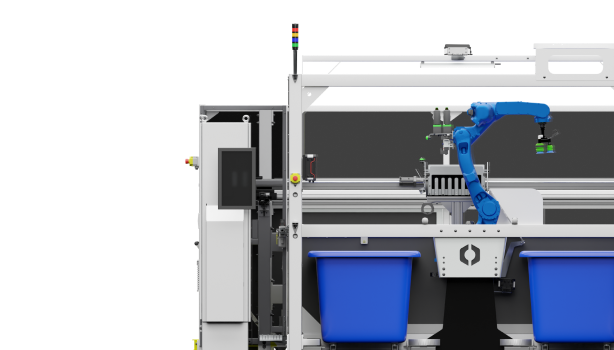

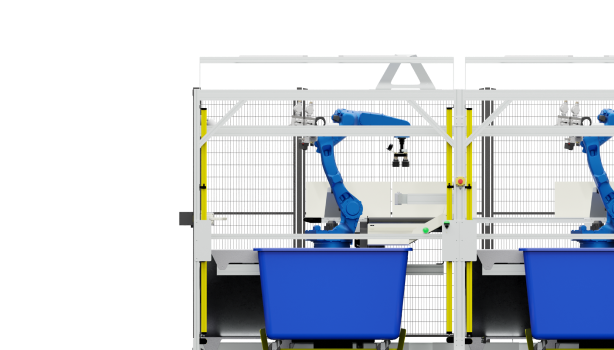

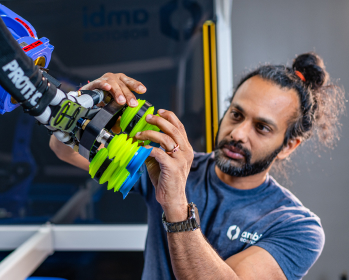

As a result, the market for package sorting robots is exploding. By taking over repetitive package handling motions, these robots increase throughput, reliability, and accuracy while reducing workplace-related injuries. The job is no longer package handler, but robot handler.

Robots are a fountain of warehouse data

Yet robots have another important benefit: by necessity they collect detailed data on every parcel they sort including metrics, timing data, images, videos, sensor readings, and more. This serves as a foundation for modern, scalable data pipelines that monitor performance, analyze package data, identify bottlenecks, and provide productivity insights. Robots are providing a real-time, scalable solution for the current pipeline demands, and laying the groundwork for a more efficient future.

With robots, warehouse operators can now have a real-time window into their facilities with a wealth of data at their fingertips to monitor and optimize performance. Performance bottlenecks that used to be identified by cross-country travel to facilities for in-person audits can now be identified automatically and used to notify management thousands of miles away. In this way, robotics systems have an opportunity to disrupt the slow and monolithic warehouse software systems that most shipping companies have relied on for decades.

Scalable AI systems will streamline operations

There’s still a long way to go in realizing this potential for robots. To get there, we need new data infrastructure. We need to build large-scale distributed pipelines that ingest tens of millions of robot actions each day and associate them with images, videos, sensor, timing and exception data. We need Machine Learning (ML) infrastructure for modern robot AI with active learning to subsampling data, connections to labeling tools, automated updates to simulation environments, and model training / hyperparameter tuning with complex sequential data. We need analytics with modern data science to find trends and bottlenecks, schedulers for sort planning, and microservices for business intelligence, automatic alerts, remote support, and large-scale data visualizations.

Robots will not only bring modern data architectures to the warehouse, they will drive the innovation of new distributed systems that support growing operations across the globe. It’s an incredible time to be doing this work. We’re creating solutions that will make an impact for generations. Are you ready to handle more?